Hourly quality inspection in process

Hourly quality inspection is in-process inspection to ensure the product quality is maintained and identify process stages well facilities.

Hourly quality inspection is conducted to ensure the product quality by the taking sample form running manufacturing processes, and test the sample for the determine actions in case any non conformity identified, on test results are comply the requirements of technical and customer specifications that process keep the lot as requirements of the job orders and quantity. In process inspection is the part of the quality control that quality engineers are taken the various types of inspection in the manufacturing processes that can be sample testing and second is hourly quality inspection in manufacturing processes where processes should be keep the works between the randomly quality engineer is conducting the product sample to identify product quality. Generally in process quality inspection is depends on the product and its size that type of quality inspection and checking process is conduct.

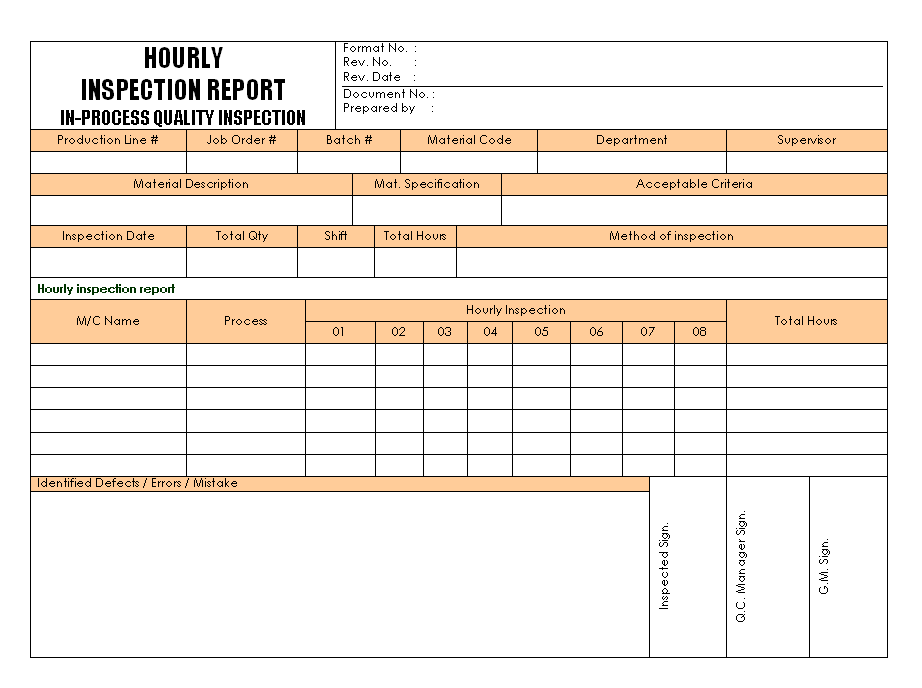

Hourly inspection process is very important to quality point of view, the process is conducted every hours that taken sample randomly to conform the product quality, this process is each product and each batch are conducted at each line. In process quality inspection’s report and other documents are conducted at the same time at the result is generated, at the end of day, whole day’s hourly inspection report is generated for the further actions on the product and process requirements to improve quality of the product and process in manufacturing activities, see below picture for reference to easier for understand hourly inspection for the quality:

In the hourly inspection report conducted on the product running in production line, defined batch numbers for the job order wise quality inspection is conducted in production to ensure the product quality and process. Hourly inspection is conduct on base of the material and material specifications and customer characteristics to comply requirement of the technical and specific requirements of customers. in the hourly inspection report, acceptable criteria are also maintain which is manage as per quality standards, product standards and method for the inspection like visual inspection, chemical testing, mechanical properties test etc.

Hourly inspection report having the most important part are testing and recording information hourly basics, which all the details are filled in the report to get the result at end of the day, in the report total standard working time are maintained which are eight hours of day in single shift, there are machine wise which process is running and first to eight hour machine’s sample is taken, in case in the two hours single product produced that also each hours sample is conducted for the testing to check the variation and deviation in the product, and end of the day product wise, machine wise and hourly quality inspection and analysis is conducted to identify the requirements of the improvement in product and process. In case during the inspection process quality engineer identified any product defects, process defects, equipment defects or raw material defects in the product or any error or mistakes are identified that full details are maintained and recorded as for improvement or non compliance.

——————————————————————

Download format in Word document | excel Sheet | PDF format

Download hourly inspection report

——————————————————————