Manpower efficiency study

Manpower efficiency study is analysis process conducted to identify manpower efficiency in particular production lines in defined time frame.

Manpower efficiency study process conducted by concern authority for analysis collected information from particular unit, particular areas or production lines to identification of manpower efficiency as considered values as defined for analysis like total timing are conducted for analysis, manpower used during the total time, production department produced materials, total minutes of production having available and target are managed as per requirement of producing materials accordingly manpower efficiency are identify for improvement of particular product, process stages and awareness training to each manpower engaged with production lines for improvement of productivity, manpower management & planning for production lines are conducted on base of the manpower efficiency study documentation. The purpose of manpower efficiency study is to identify current productivity of manpower, the efficiency through management determine loading materials, arrangement of concern requirements and order management, hence the improvement of manpower efficiency is managed as conducting each production lines, department and units’ information and analysis efficiency requirements for targeting for improvement, preparation of action plan to implement at workplaces where very low manpower efficiency identified and its priority is managed as per manpower efficiency study documentations and concern reports.

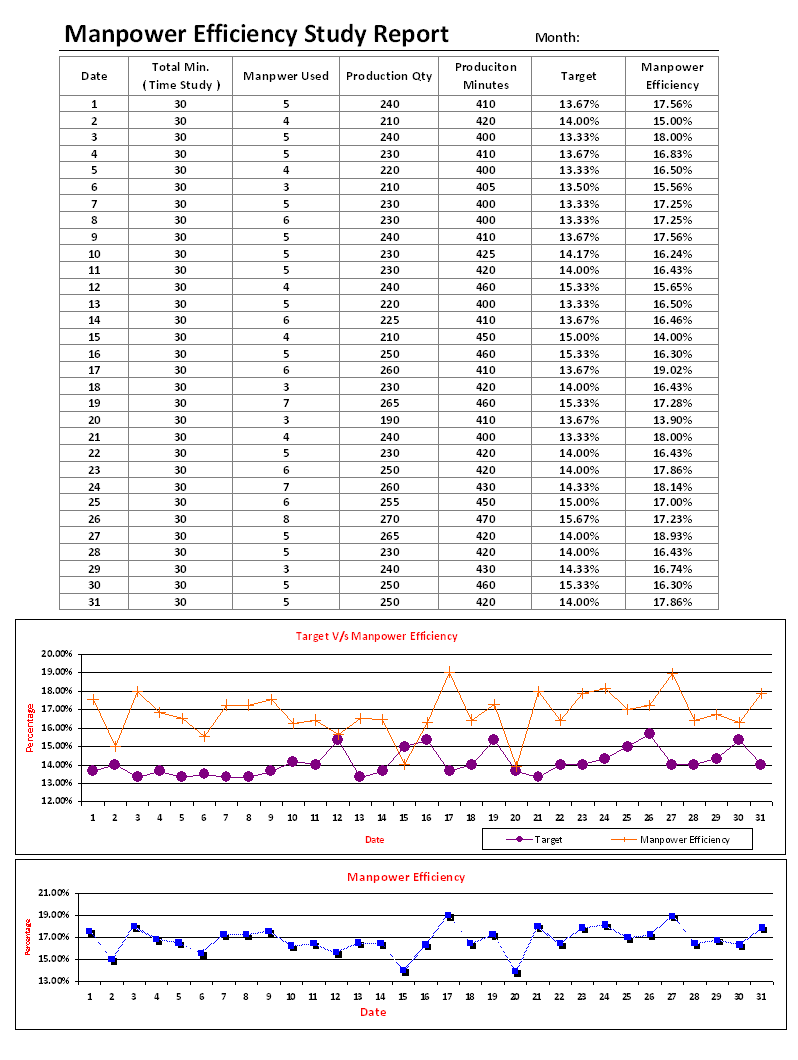

The production lines are managed by concern manager to considering requirements of productions, current orders & time frame that allocated by management for producing particular materials with values quality requirements, so it is important that each concern employee should work with maximum productivity in workplaces to improvement of overall production targets with acceptable quality to customer end applications, hence deployment of manpower is managed accordingly, generally manager or manpower management team know that each employee individual efficiency and on based the deployment of manpower and its concern management are handled and management can get through individual efficiency which raised by individual employee monitoring, target provided and studies that conducted by manager through monitoring on each employee. The documentation are managed for recording information, determine action plans and implementation as priority identified, see picture below given as example format of manpower efficiency study report format for education purpose:

Manpower efficiency study report is used to recording information of manpower efficiency and its concern study to implementation of actions to improvement of overall productivity, the system is deployed for individual improvement and sustain processes to minimize possibility of mistakes, errors of humans are generally identified and occurred in previous records. The analysis records are help to determine individual employee implementations, department and production lines management information are handles. The above format is managed information of department or unit manpower are conducted to monitoring time frame, the records are indicates that the targets are managed as per production quantity, manpower available with department and time are conducted for the production that target values are managed, if the numbers of workmen are available are depends the target values, hence its considering the total number of manpower and production quantity produced during the time frame are considered and on base of the manpower efficiency are identified.

————————————————————————————

Download format in word document | Excel Sheet | PDF format

Manpower efficiency study report

————————————————————————————