Manufacturing Process observation system

Manufacturing process observation system established to ensure the processes’ sequences and interactions are complying requirements of standards & stable for reliability to producing material.

Manufacturing process observation system is established in the manufacturing / production unit to monitoring each manufacturing processes’ stages, sequences of processes and interactions between each process having a stability and reliability for the producing materials with best quality, all manufacturing process should be complying and act as requirement of the processes standards, manufacturing product standards and customer requirements, motive of the observations is identify treats in the processes to improvement of rhythm of manufacturing process to process, maintain product quality by follows standards of manufacturing process and fulfillment of each customer requirements, technical requirement and product standards to considering close product tolerances. It’s a basic need for each manufacturing unit to frequently monitoring on each manufacturing processes to identify failure causes, time management and improvement of productivities of machinery and equipments and its can possible if the proper observations, monitoring system is deployed and working on level to excess improvement can possible in manufacturing levels. Utilization of machinery / equipment is major factor for the manufacturing processes, if the time management, material management, product planning is having a gap that cause lower utilization of machinery / equipment and manpower, best ways to frequently observation on each elements are used in manufacturing processes, managing and deployment on requirements of processes, setup monitoring through devices, manpower, automatic systems etc, to collecting data from processes, on base of collected data proper analysis are possible to conduct to identify treats, time management lapse, unorganized material management, unplanned machinery and equipment used in manufacturing, manpower and other important part of manufacturing process are possible to identify and proper action plan preparation and immediate action implementation are conducted on identified treats and its possible if the proper setup are established.

Manufacturing process observation system and its documentation, improvement and strictly follows in the manufacturing unit’s responsible of production manager / works manager, the concern manager is looking after all the operations, collecting information, analysis data and identified cause of leakages in the system for proper action plan is preparation, all the actions plans are conducted with top management meeting & on approvals of top management all the action plan is deliver to processes, on after implementation of action plan, once again observation is conducted to check out its effectiveness, reliability, stability of the processes, because some time happen that some actions are not effect immediate like a shift time change over, lunch breaks, maintenance activities etc factors are directly effects on processes time consumption and its not easy immediate applicable hence the requirements of the actions are not fulfilled immediately, its take some time to improve by some actions by motivations or other ways. On new process observation get the clear picture of action plan effectiveness which can be conducted on after quarter of actions implemented, but the regular monitoring is also needs to conducted for the watching the situations, action plan implementation road map and other conditions of the manufacturing processes and action plans. The concern manager is responsible and accountable for each activities of manufacturing process hence the whole process of identification, monitoring, action plan, implementation, monitoring and re-observations and improvement of overall equipment efficiency, productivity and manpower awareness.

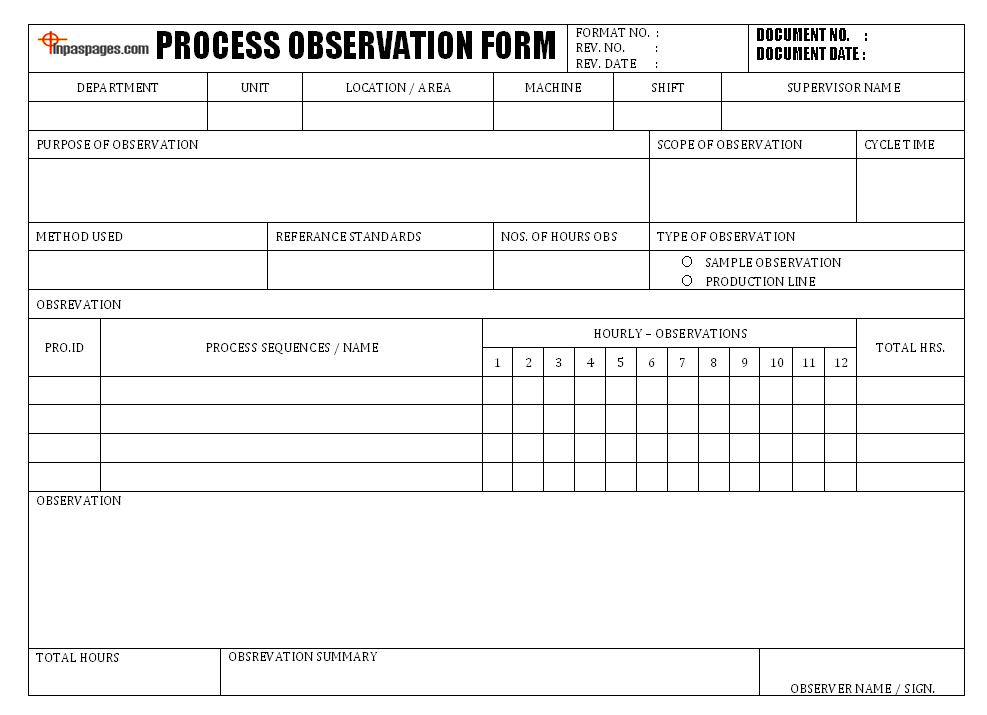

Manufacturing process observation system is covered all the manufacturing processes, supporting processes, all machinery and equipment installed at manufacturing facilities, manpower engaged with manufacturing and shift time dedicated for manufacturing processes are main requirements for the manufacturing processes observation, in the observation, observer team is conducting each manufacturing activities to compare with time frame is decided as per production norm, the production norm is center for the manufacturing processes, as per identified process cycles are consider by observer team for the comparing each processes end and start up, in case any time slab is identified that observation team is reporting in process observation form which is document for the collecting information at the time of observation visit at plant i.e. at manufacturing facilities, see picture below for reference format given of process observation form for education purpose:

Process observation form is complete format to covering all manufacturing processes which is conducted for producing materials, in the production observation system can be conducted as department wise, process wise or as per required unit level, the system is supporting any kind of observation required for process monitoring. Manufacturing processes observation is conducted as per specified methods which is defined to reference standards to conduct which is standardize as per international standards to ensure the process observation and its method to inspect the processes, sampling for observation, visual inspection and audit of production line should covered all the requirements to comply facilities observation requirements. In the manufacturing processes, each observation is conducted on process sequences and its should be practically hourly observation is conducted to clear view of observations, fact finding and other treats can easy for identify.

Observer is conducting all the processes and in the process observation form, all the concern details are fulfill for recording and further analysis purpose, on base of the records all required actions, improvement plan is conducted hence the records are clear and state to action plan can proper improve in manufacturing facilities. On base of the process observation form management is conducting further action, concern manager of department, production manager is also involved in improvement plan and records of process observation form copy are files to compare with upcoming action plan’s monitoring and re-observation managing.

——————————————————————–

Download format in word document | Excel Sheet | PDF format

Process Observation form

——————————————————————–