Manufacturing process parameters controls for product standards

Manufacturing process parameters controls for product standards are established to controls tolerances of product’s requirement as per specifications.

Manufacturing process parameter controls are established for improvement of the product quality where product sizes and its acceptable tolerances are considered, product tolerances should be closed as requirements of end applications, generally customers are provides required tolerances on product sizes that needs to maintain and according to product sizes’ tolerances whole manufacturing processes are managed. Customers are provides product sizes’ tolerances to managing its end application and its standard requirements, and as per acceptance of customer, supplier is producing materials to controlling on manufacturing process parameters to maintain standards. generally each product’s standards requirements are maintained during manufacturing processes but some customers required very close tolerances or close tolerances are good production practice are considered.

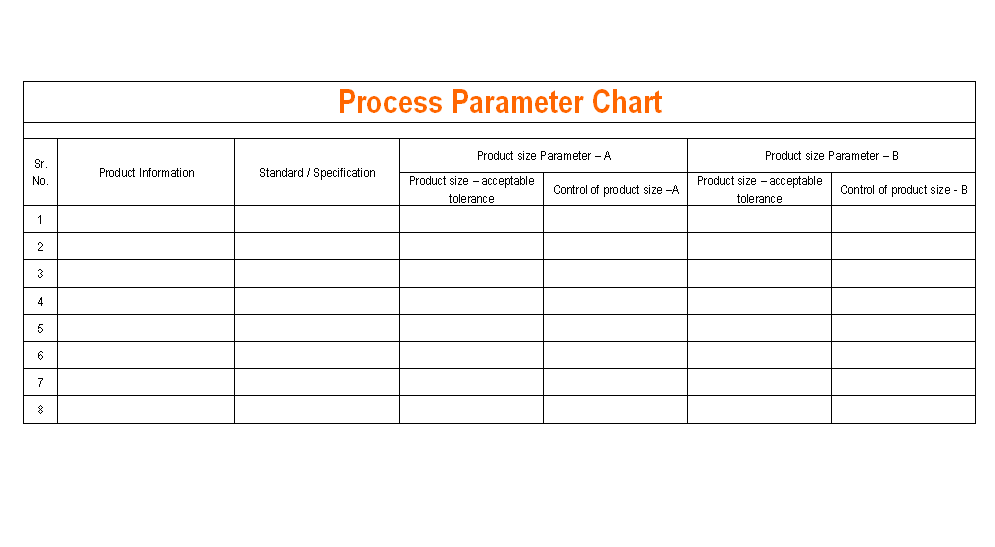

To maintain tolerances on product, general manager / works manager is frequently monitoring on the production processes and timely conducting product sample for testing, managers are conducting sample and verify the product sizes’ tolerance and recorded as per standard requirements and proper controls deployment during production. The statistical methods are also used in production lines for controls over process parameters and product sizes’ tolerance maintain. Manufacturing process parameter controls are defined by general manger and responsible for conducting, monitoring and determine controls on manufacturing processes. Department managers are responsible for provide information required to monitoring and analysis, hence also responsible for controls measures are deployed as per general manager instructions & monitoring on follow up of procedures to maintain system in workplace. For the monitoring and controlling on the process parameters, concern manager is refer manufacturing process parameter chart to record information of current settings and actual production lines activity. See picture below given as example format of process parameter chart format for education purpose:

In the process parameter chart, all the product information, product standard and its specification wise, production sizes are mentioned with its applicable and acceptable tolerances requirements, there are also controls of product sizes are mentioned to concern manager can measure sample product from production line at time of production, in case any variation is identified that manager can take action on processes to control over variation and deviation in production lines for product. Process parameter chart is helpful format which is used in mostly engineering and heavy machinery manufacturing company or concern suppliers are used for end application compliance of standards and its applicable requirements. The documentation for manufacturing process parameters are maintained as per lot or batch which all machine and process details are involve for analysis, the information are helps to identify machine wise, process wise variation and deviation in product sizes and is tolerances to analyze which machine and in which process most variation is identified, on base of the analysis concern manager / general manager determine action to minimize tolerance as per standard requirements. Record analysis is important job for management where all the product sizes and its acceptable tolerances are need match, and as per general suggestion management is deployed controls of product sizes or amending on current controls of product sizes to managing tolerances on product which all the parameters can achieve as per standard or customer requirements.

————————————————————————-

Download format in word document | Excel Sheet | PDF format

Process Parameter Chart

————————————————————————-