Parts failure and fix process

Parts failure and fix process is conducted to identification of part’s failure and solution for particular part’s in line with standard requirements.

Parts failure and fix process is established, maintained and update for conducting part’s concern part’s failures during inspection processes, in-process inspection or during manufacturing / production lines by concern supervisors, the part’s failure and its inline with solutions are identified by teams for fix the problem occurred in the part’s failure and fix parts for customer satisfaction. Part’s failure and fixing are conducted by concern quality team to conducting various testing on parts, and identify source cause for problem raised, the reasons behind the failure are important to identify and monitoring and controls over the process, materials or any activities that part’s failure are occurred during processes, manufacturing activities or any other activities. The documentation for the part’s failures are identify during the various manufacturing processes by concern department, or any quality concern inspection activities, but the fix of part’s failure is independent activity that conducted on registering of failure of problem, and the team are conducting those activities for fixing particular error / mistake or cause of failure.

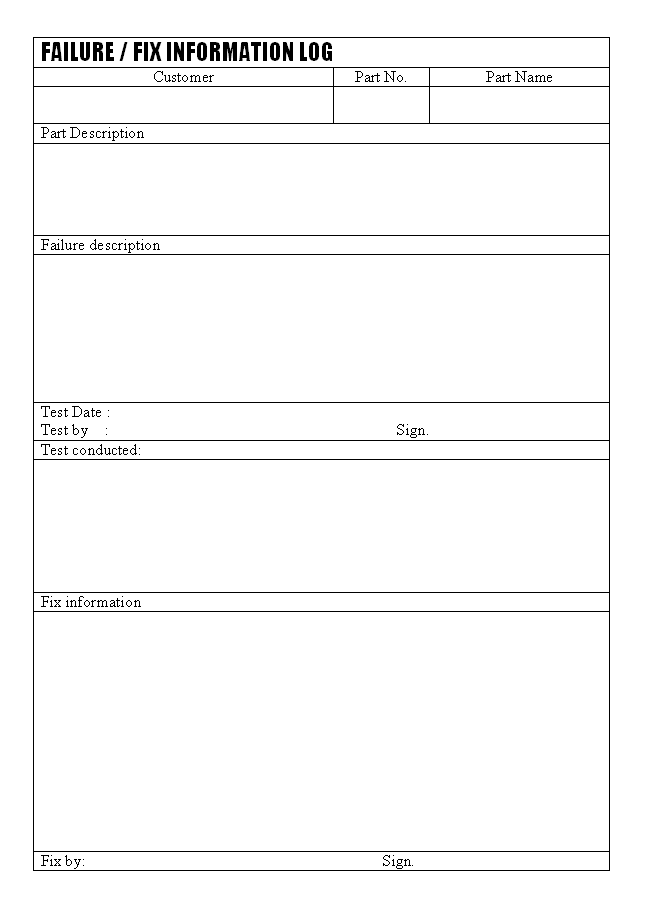

Part’s failure and fix process is conducted by quality department, quality manager is responsible for preparation of procedure and deployment in the system, quality manager is also responsible for selection of qualified inspection team to conduct test on the parts that identified failure to find out root cause of the part’s failure and also to reach to source causes of failure to determine action plan for solutions and fix the parts as per standards. Quality inspection team is conduct failed part for inspection process, in the inspection process quality inspection team is manage various test required and applicable as per parts standards and as per customer requirements, during the various tests quality inspection team determine root cause and source causes of failures. The documentation for whole process is conducted and manages to report quality manager, the document prepared and submitted to quality manager is failure / fix information log, see picture below given as example format for education purpose:

Failure / fix information log format is used for recording information of part’s failure and its solution identified by quality inspection teams to conducting various required tests as per part’s applicable standards and customer requirements to meet end application requirements. Failure / fix information log is register and recording information of failure are raised during manufacturing or various supporting processes, and the same way quality team identifies solution and fix the problem for particular product and inline with solutions are managed in format.

————————————————————————–

Download format in word document | Excel Sheet | PDF format

Failure / fix information log

————————————————————————–