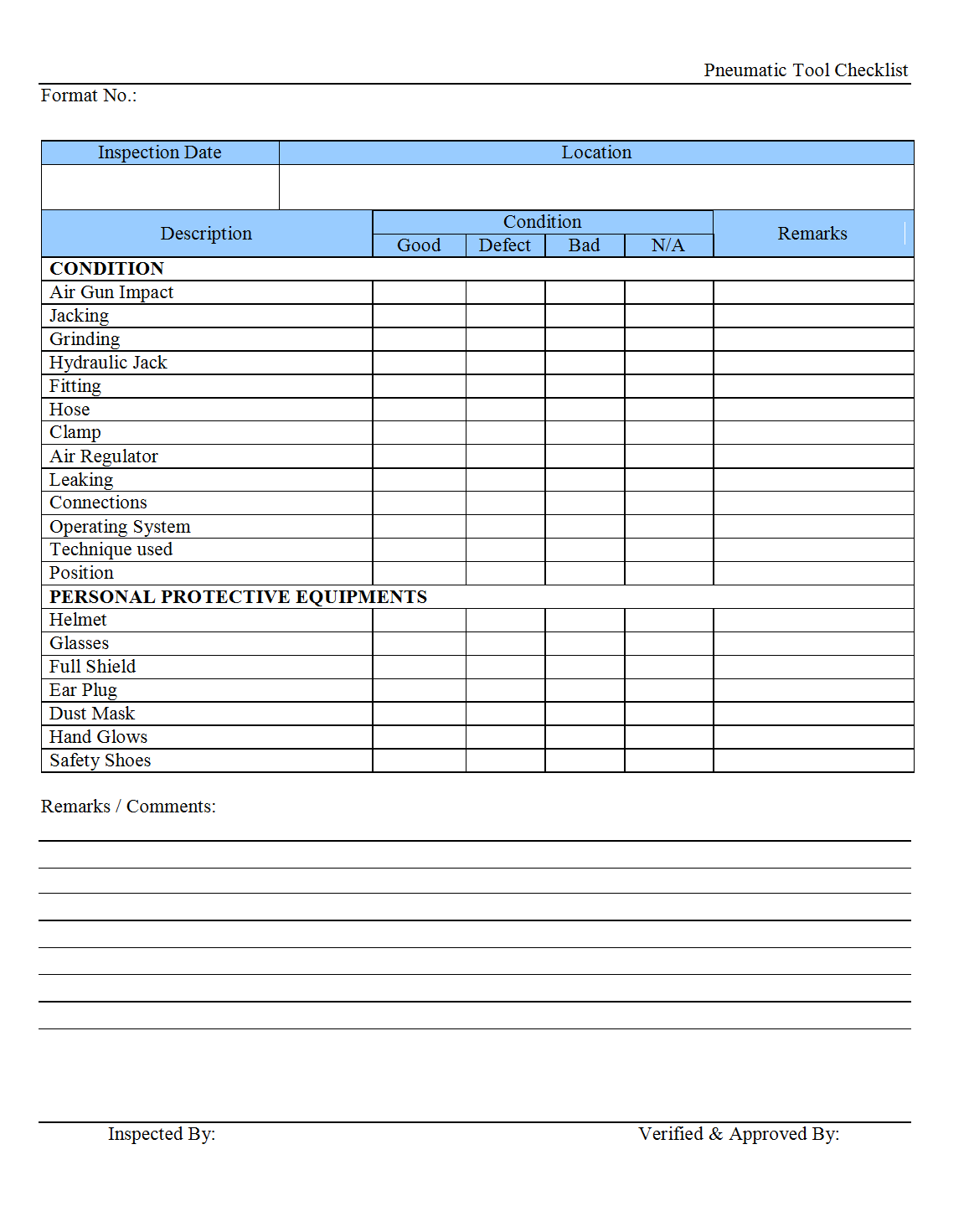

Pneumatic tool checklist is maintenance related checklist document. It may help to ensure that the each part of the pneumatic tool is properly maintained, and its functioning well.

Pneumatic tool checklist format

Checklist Guideline

- Designate a competent person responsible to do inspections at the prescribed intervals.

- Inspect items at prescribed intervals or more frequently as may be necessary if conditions have changed.

- If an item is in order, mark the YES column. If an item is not in order or defective, mark the NO column and specify the defect &/or action taken.

- Equipment is defective it must be tagged “Defective” and must be reported to the person responsible for the repair of the equipment. If the equipment is beyond repair it must be taken out of service.

- This inspection checklist relates to production related portable powered hand tools: angle grinders; drills; sanders; pedestal grinders; pedestal drills; and similar electrical powered hand tools used for construction, repair and maintenance work activities which connects with a plug to an electrical outlet socket.

Following information need to inspect during walk sheet, inspection checklist is filling up:

- Air Gun Impact

- Jacking

- Grinding

- Hydraulic Jack

- Fitting

- Hose

- Clamp

- Air Regulator

- Leaking

- Connections

- Operating System

- Technique used

- Position

- Helmet

- Glasses

- Full Shield

- Ear Plug

- Dust Mask

- Hand Glows

- Safety Shoes

What can be inspection criteria? – Examples

- Unit number – clear and visible – includes extension cords

- General condition of unit – clean; free of grit; free from damage and defects

- Guards – in place and secure (where fitted)

- Rotating bits securely fastened and in safe condition

- Tools governed not to over speed – check tool RPM versus working bit RPM

- Activating switch/ lever in proper working condition

- Pneumatic hoses uses and in good condition

- Hose connection to tool in good condition – proper hose clamps used (not wire)

- Hose joints properly connected – proper hose clamps used (not wire)

- Suitable facilities provided for safe and secure storage when tools are not in use

Download ready made format for pneumatic tool checklist with below links:

EXAMPLES, SAMPLES & FORMATS: Download