Production batch documents – quality department

Production batch documents are describing production batch information that managing production structurally and accurately.

Production batch documents are established to managing records of production batches managed for structural production of each materials, machine wise and requirement wise of customers, the production batch are structural distribution of customers ordered in production lines, the production batch are conducted when the customer ordered are used and impossible to managed full lot in the manufacturing that management are manage the some quantity as the batch and load in manufacturing processes batch wise to easier for tracking and identification of the production.

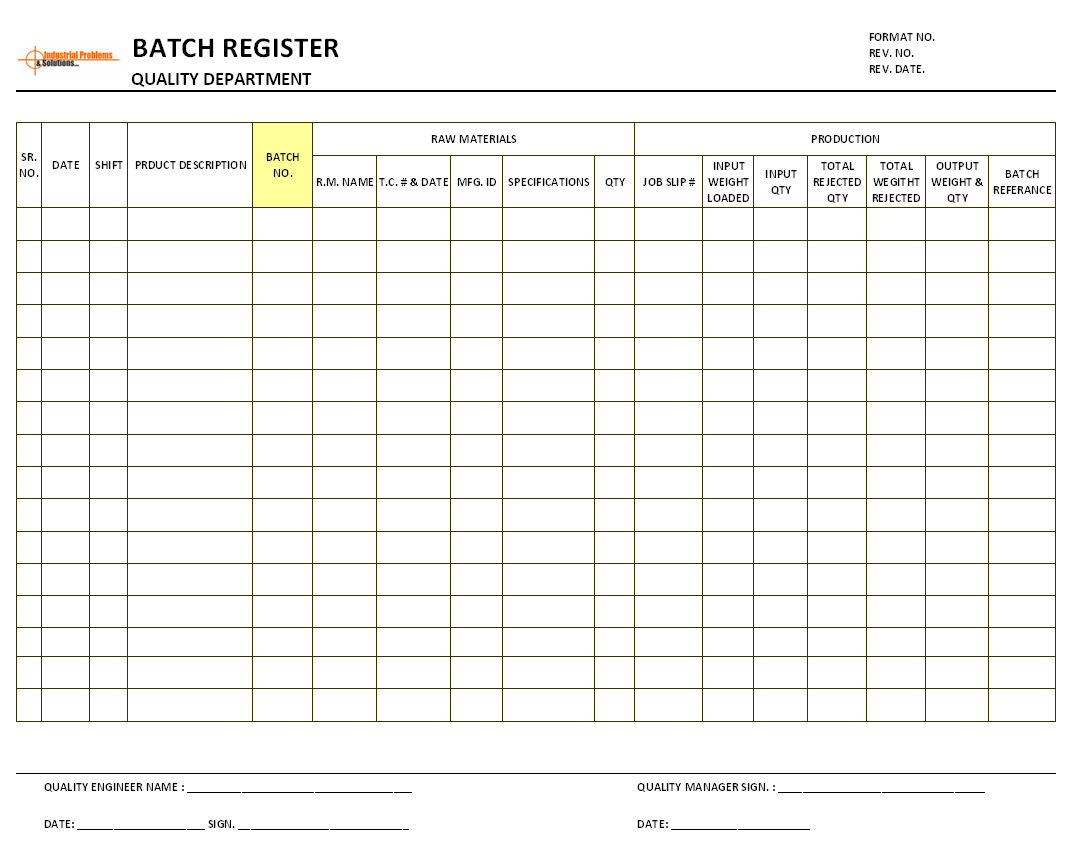

Production batch established by management for effective manage each product in manufacturing process, when the marketing team received any order from customers and passed to production manager, production manager is bifurcate order quantity in batch numbers for loading in manufacturing processes, the batch numbers will be identification of the lot manage by production manager, and till finish product the materials will be attached with batch number, this is the system that help to tracking the materials at the various places are under the processing, and in case any production processes or any other defects identified that whole order can possible to save if the materials are managed batch wise. See picture below given as example format of batch register that used for recording each batch managed in production lines, and the records are managed by quality department for the comparing each batch wise records to identify product quality, the process is maintained for batch registers and its requirements for quality concern. Below picture given for education purpose:

Batch register format is used to recording production batch concern information where each batch that conducted in production lines are managed and recorded for batch analysis, the records are managed by quality engineers for identification of the quality requirements, identification of batch defects or any issues that product quality can directly affects of violating customer terms and requirements of end applications. The quality teams are managed the records as raw materials concern and same the process in the sequences in production lines are recorded to identify interactions of each process on materials, and records that materials are rejected, and considered in waste, on base of the records quality team is conducting processes of analysis and instruction to production lines for quality improvement.

——————————————————————————-

Download format in word document | Excel Sheet | PDF format