Quality operating system – Procedure & Methodology

A quality operating system is a methodology. QOS disciplined approach works systematically to standardized business practices and operate new product development and manufacturing operations.

Overview

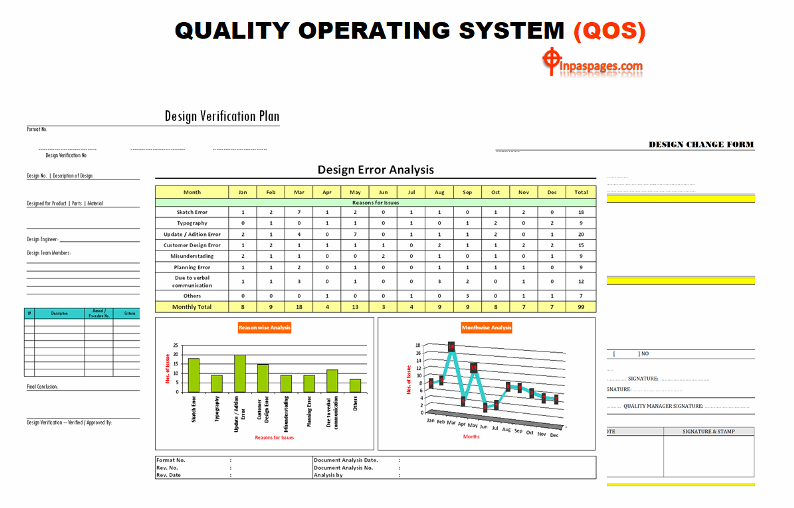

Most organization are expecting health management system for improve product quality and customer satisfaction. here we discussing, how quality operating system organize design & development and its procedure. Organization can apply quality operating system in product design & development stage.

Quality operating system: Design & Development Procedure & system model

The organization are establish standard procedure for design & development for new product development. And / or implementation of existing product to extract quality requirements.

The quality operating system needs to proper planning of designing and development for new product. As well existing product in case of improvement, modification of amendment in existing design. The amendments needs to submitting to concern authority. All the require details like sketches, drawings, technical sheet, applicable application requirements. Standard applicable causes reference for implementation of product as per customer requirements are also submit to authority. The customer provided documentation are also needs to prefer to match the existing design and customer expected product. Design and development should include prototype and pre-production, analysis condition for regular production.

Quality operating system: Design & Development – Planning Management

The design and development team collecting information from various required sources. Such as customers, existing products designs and quality approved documents. The design team manage the sample, sample development responsibility managed by production lines according prototypes implemented by design team. The production / general manager is responsible for the verify samples and review it. The information and data of each samples design and developed upon the documentation used for the producing samples. All the approvals and its concern processes are managed according to standards and its applicable end application requirements.

Quality operating system: Design & Development – at initial Stage

The basic stages of the quality operating system are designing and its reviews to manage samples on initial stages. Management team is review the design and information. The general manager is responsible for the monitoring on each activities and appropriate supervisors are responsible for conducting this processes of the design review. The general meeting of management team also participation needs to improvement of quality operations of the product. The changes made and required to the design / documentation during to the reviews should made in accordance with specific clause and documentation of design changes.

The team collect the information where all the quality requirements should be complied. The general inputs are from customer, internal checklist and documentation, end application requirements that can be statutory and regulatory. The validation process is final stage of the quality operation, hence the approvals of each design, article should be performed by manufacturing on final approvals. The documentation records are maintained as per standard records management system that is documentation system.

Design & Development – inputs:

The design & development team collect details from customer for use as inputs. The details are previous design, design information checklist, and related to technical information. Regulatory requirements and statutory requirements of local government bodies are necessary to consider as inputs for design phase. Management team are review and verify all records. Try to put in practice, all documents & processes are must review and verified by management, before in act. Actually, this is common requirement of quality operating procedures and system model requirement. Once the verification and approvals are complete, release the documents for further actions.

Design & Development – outputs:

Development outputs are establish through bills of materials (BOM) and manufacturing drawing. Make the standard practice for release the final print with assigning a revision letter by designer team. The details must be collaborated with revision information and initials of the sample details in appropriate formats. The designer provide the master records in line with drawing & manufacturing requirements. Generally, engineering team is responsible for conducting the copies of all drawing and master records. Authority review and approve bill of materials, and drawing. Once the verification are complete, all the related documents are release to appropriate department.

Each section, stages, and phase are correctly organize in the quality operating system model. Quality operating system model’s general requirement is outputs validation conduct properly. Generally, head of department / authority validate the procedure and related document. Customer approvals for first article are also part of the validation process. Once the customer are approve first article i.e. acceptance of first production part, organization can start mass production and arrange delivery schedules.