A housekeeping inspection checklist may cover all inspection information includes cleaning, waste disposal, storage and sanitation processes. Obviously it may prevent the workplace hazard free such as chemical exposures, slippery, fires, etc.

Overview to housekeeping inspection checklist

Company having a latest technology, skilled employees and workmen and best quality material able to produce, but the organization is not proper clean, dust and material are deploy here and there can directly effect on quality and customers that visit the plant, that is the reason that housekeeping is primary requirement of the company. For the housekeeping sufficient people that know & able to organize housekeeping task at the plant level.

Housekeeping activity are also need to audit time to time, for the auditing of the activity housekeeping inspection are perform in company to take advantage of the in auditing, company creating some task to need to perform during the audit, some points that already decided for the audit for the comfort to auditing the housekeeping process and its concern activity.

The housekeeping inspection checklist are using by auditors to avoid or leakage of any activity during the audit, each checklist details are help to auditor for the next stage of the audit.

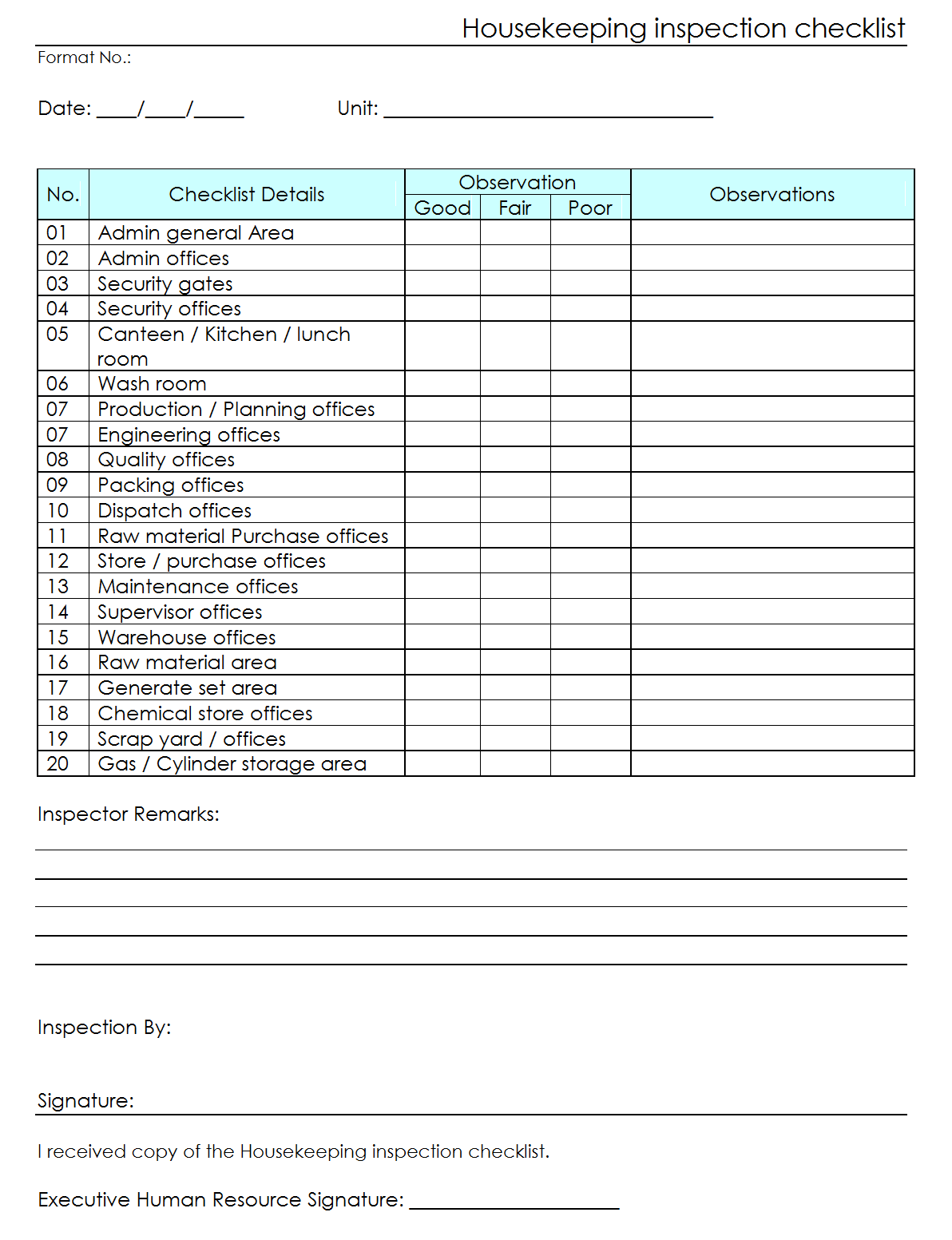

Simple housekeeping inspection checklist template

Here ready made housekeeping inspection checklist available for download with following links:

What to include in housekeeping checklist?

It is normal when you take any task, you may confuse where from to start. The easier way to understand your sequence of processes. Normally, in any business raw materials is initial stage of the processes. Hence, you have to start with your raw materials department. Here are some steps by step description that may generally every organization may need to follow:

Raw material & Planning area

- Is there any Unwanted material lying on floor (Outside the gangway) of processing area?

- Do people wear appropriate personal protective equipment (safety Shoes, Hand gloves) during process?

- Are the material is stacked / stored at the specified height or more than that?

- What there any loose wire or open connections?

- Verify there any leakage of oil / coolant on floor?

- Check the strength of slings / Ropes being sufficient? Records of Test certificate.

- The condition of Rope / slings being satisfactory – Not too old OR damaged OR worn out? Are they periodically and jointly inspected with Maintenance Dept.?

- An Instructions for handling & Storage available? Are the same are followed?

- Instruction of working with hazardous is there? Employees are following it or not?

- Material Handling & disposal of Hazardous waste given to Authorized person?

- The crane or Lifts Examined once in last 6 months by authorized and competent agency? Evidence? Or as per laid down standards, Is the loose metallic & plastic strips, plastic sheet and other packaging material are disposed of as per Standard?

- Entire area being clean without grease, Oil, chemical, Fumes, chemical Vapor?

- You have to check the material handling trolley being in good and safe working condition?

- The material is Handled, stacked / stored / Preserved as per MSDS? Is a copy of MSDS available?

Storage area

- Do people wear appropriate personal protective equipment (safety Shoes, Helmet, Hand Gloves) during material loading / unloading activity?

- Is there any proper arrangement for working on height in store? (Condition of ladders, tables or any other arrangement)

- Are there any Material Lying on work floor having a potential to harm?

- Is there separate place for Hazardous material & adequate display of signage/ warnings/ MSDS (If required)?

- Is stamping & verification carried out for standard weights / Electronic weigh machines once in a year? Evidence?

Manufacturing area

- Is there any material lying on floor (Outside the gangway) of Processing area?

- Do people wearing appropriate personal protective equipment (safety Shoes, Hand gloves) during process?

- Check there any leakage of oil, Air, coolant from machine? Is there any arrangement to prevent leakage?

- Verify there any rotating equipment without guard in area?

- There is any damaged of Electrical appliances?

- Are there any loose wire or open connections?

- To check there any spillage of oil on floor from machine and process?

- There air leakage from hose pipe / magnetic coils?

- Do people follow work instruction?

- Is Material lifting and transferring device are Examined once in last 6 months? Evidence?

Quality Assurance & Control

- Is there any material lying on floor (Outside the gangway) of Inspection area?

- Do people wear appropriate PPE’s (safety Shoes, Hand gloves) during inspection?

- Is there any rotating equipment without guard in machining area?

- There are any damage of Electrical appliances?

- Check there any leakage of oil / coolant on floor?

- Verify there any rubbish like MS wire pieces, cotton etc. on floor?

- Do people follow work instruction?

- Is Hoist or Lifts Examined once in last 6 months? Evidence?

- Are the MS wires, PP strings, used cotton waste stored and disposed of separately as per W. I.?

Maintenance Activities

- Do Maintenance people use proper PPE (safety shoes, Helmet, safety Belts, APPROPRIATE Hand gloves for Maintenance work?

- Is do Maintenance People use standard Tools?

- Do Maintenance Peoples tested chain pulley blocks once in a year? Evidence?

- The working personnel take Work permit for Working on Height or Hot work etc.?

- Are there work permit valid & approve? (if any)

- Do Maintenance people use safety Belts on height?

- Is lifting machine, chain, rope or lifting tackles examined once in a year? Evidence?

- Is Periodic Checking & Testing of Pressure Tanks or Vessels is carried out with evidence by competent and authorized Agency?

- Verify record available for testing of Cranes?

- Check there proper arrangement for disposal of solid waste, cotton waste, paint scrap, rubber scrap, fiber scrap contaminated?

- Is record available for Inspection & Testing of pressurized vessels OR air receiver tanks used in factory?

Daily, weekly, and monthly housekeeping checklists

OK, you are decide to perform each housekeeping tasks at entire workplace or organization. You have to take care for the scheduling and maintain it accurately. We suggesting, make your schedule more convenient. Such as daily, weekly and monthly housekeeping schedules may give a comfort to take the task of housekeeping.

The reason behind the schedules for the housekeeping is, it may reduce the workload. Obviously, it is impossible to take conduct housekeeping of entire organization on same time. Hence, make your schedule reasonable.

- Maintain your schedule as define for housekeeping works.

- Check, learn and improve the checklist points.

- Modify schedule if any more time require at any particular place.

- Define the standard places (everything’s at its own place), processes and change the habits.

- Remark and add, if anything misses in the checklist.

Simply, the regular checklist may helpful to improve the work environment, and individual habits.

EXAMPLES, SAMPLES & FORMATS: Download

Related:

- OFFICE SAFETY INSPECTION TIP

- EMERGENCY INSPECTION CHECKLIST

- HOUSEKEEPING & SAFETY AUDIT CHECKLIST

- DAILY LABORATORY / OFFICE CLEANING RECORD SHEET

- CLEANING LUBRICATION INSPECTION TIGHTENING SCHEDULE AND FORMAT

- SWEEPER ATTENDANCE SHEET