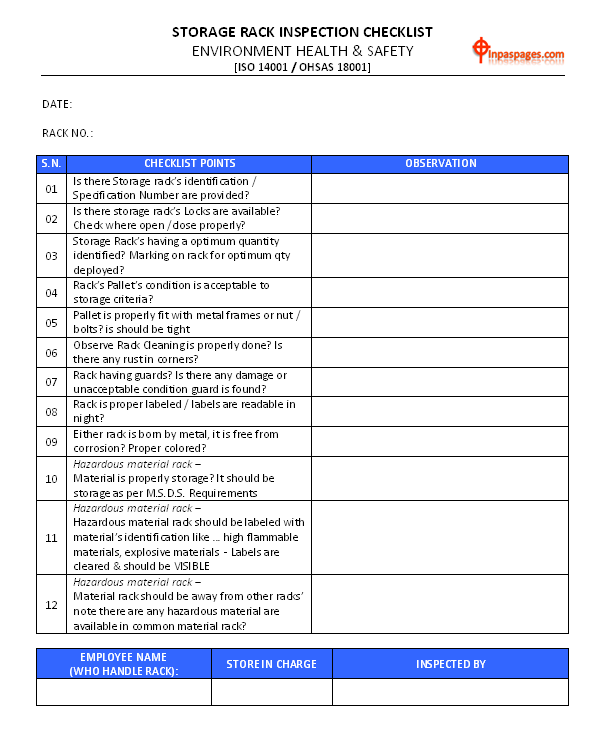

Storage Rack inspection checklist

An organization follows International standards like ISO 14001 / OHSAS 18001 – environment health & safety that storage & material movements safety & concern issue must be aware, for the increase of the storage department safety, here we are discuss on subject on consumable goods storage / chemical storage & other hazardous material storage that can be possible in single room with different racks.

Storage room with rack is systemic storage of the material, but there are also possible to little mistake can cause accidents and financial losses of company. For avoid such accident that need to frequently define the criteria of the inspection with follow strongly to eliminate possible accidents and losses.

Storage rack inspection checklist covered following points:

- Is there Storage rack’s identification / Specification Number are provided?

- Is there storage rack’s Locks are available? Check where open /close properly?

- Storage Rack’s having a optimum quantity identified? Marking on rack for optimum qty deployed?

- Rack’s Pallet’s condition is acceptable to storage criteria?

- Pallet is properly fit with metal frames or nut / bolts? is should be tight

- Observe Rack Cleaning is properly done? Is there any rust in corners?

- Rack having guards? Is there any damage or unacceptable condition guard is found?

- Rack is proper labeled / labels are readable in night?

- Either rack is born by metal, it is free from corrosion? Proper colored?

- Hazardous material rack – Material is properly storage? It should be storage as per M.S.D.S. Requirements

- Hazardous material rack – Hazardous material rack should be labeled with material’s identification like … high flammable materials, explosive materials – Labels are cleared & should be VISIBLE

- Hazardous material rack –Material rack should be away from other racks’ note there are any hazardous material are available in common material rack?

Generally above points are sufficient level of the safety of storage rack can keep in company, there are also can possible to add the points are requirements of company, storage style, material priority, racking system can be different in each organization can possible to all points are not effective in those cases.

Download Storage Rack inspection checklist in word Document format

Storage rack inspection checklist templates download

Storage rack inspection checklist samples / examples download