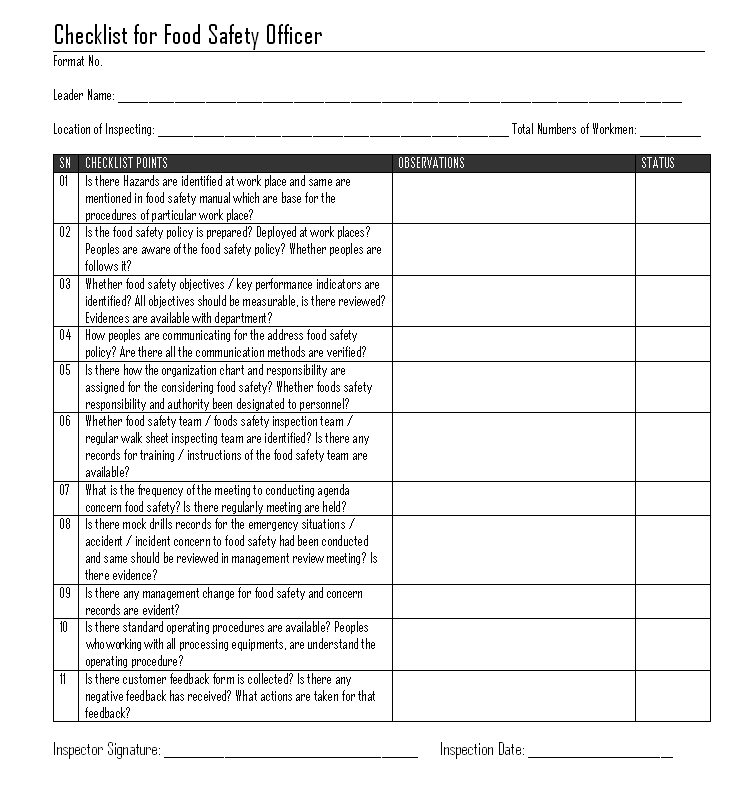

Checklist for Food Safety officer

The organization has needs to established, documented, implemented and maintained an effective foods safety audit system which is updated when necessary in accordance to internationally accepted system. The food safety audit system is helps to maintain specifies the products, processes and manufacturing workplaces that are addressed by the food safety audit system. The audit processes should be conducted to cover up all the processing areas, standardized requirements to maintain food products.

The organization had ensured that the food safety hazards that may occur in relation to products within the standard covered area are identified, evaluated and controlled in such a manner that products don not directly or indirectly harm the customer. The communicates appropriate information throughout the food chain related to safety problem related to its products. The food safety audit team should conduct the audit to covered all the parts of the organization. The organization needs to monitoring on each objective that helps to implement food safety and audit team is conduct first objectives as on initial audit, general objectives of food industry area:

| Objective | Current status | Target | Period |

|---|---|---|---|

| Food safety complaints | |||

| Machine Break down time | |||

| Customer satisfaction level | |||

| Packing material wastage reduction level | |||

| Food safety training to all employees |

EXAMPLES, SAMPLES & FORMATS

CHECKLIST FOR FOOD SAFETY OFFICER IN WORD DOCUMENT DOWNLOAD FREE

CHECKLIST FOR FOOD SAFETY OFFICER IN PDF FORMAT DOWNLOAD FREE

CHECKLIST FOR FOOD SAFETY OFFICER TEMPLATES DOWNLOAD

CHECKLIST FOR FOOD SAFETY OFFICER IN JPEG, PNG FORMAT DOWNLOAD

The objective is main part of the food safety audit, because all the implementation and actions planning are conducted to considering objectives of organization, hence each audit documents should have covered and start by objectives are best way to auditing. Along with food safety audit, regular audit is important role in food safety management system i.e. weekly or monthly audit which is conducted by safety officer to visiting each plant and area to identify hazards in workplace. The safety officer is used the checklist which is pre-defined points are made points to consider existing plan design, processes and activities and all the auditing points are maintains accordingly. Here I given blow points which is general for all type of food industry:

- Is there Hazards are identified at work place and same are mentioned in food safety manual which are base for the procedures of particular work place?

- Is the food safety policy is prepared? Deployed at work places? Peoples are aware of the food safety policy? Whether peoples are follows it?

- Whether food safety objectives / key performance indicators are identified? All objectives should be measurable, is there reviewed? Evidences are available with department?

- How peoples are communicating for the address food safety policy? Are there all the communication methods are verified?

- Is there how the organization chart and responsibility are assigned for the considering food safety? Whether foods safety responsibility and authority been designated to personnel?

- Whether food safety team / foods safety inspection team / regular walk sheet inspecting team are identified? Are there any records for training / instructions of the food safety team are available?

- What is the frequency of the meeting to conducting agenda concern food safety? Is there regularly meeting are held?

- Are there mock drills records for the emergency situations / accident / incident concern to food safety had been conducted and same should be reviewed in management review meeting? Is there evidence?

- Is there any management change for food safety and concern records are evident?

- Are there standard operating procedures being available? Peoples who working with all processing equipment, are understand the operating procedure?

- Is there customer feedback form is collected? Is there any negative feedback has received? What actions are taken for that feedback?

You would also like to read: