Control of Monitoring & Measuring Devices

Control of monitoring & measuring devices process is established to ensure devices are properly calibrated & accurate to complied standard requirements.

Control of monitoring and measuring devices process is prepared and deployed in internal management system to controls over monitoring and measuring devices through identify procedure for monitoring & measuring devices to controls on activities, the process is deployed to ensure the devices are properly calibrated; all measuring and monitoring devices are verified by qualified engineers and verified as per standard requirements. The system is required for improvement in product quality and maintains system for monitoring and measuring devices are used in quality department to inspecting, measuring & monitoring product processes and its activity in manufacturing processes.

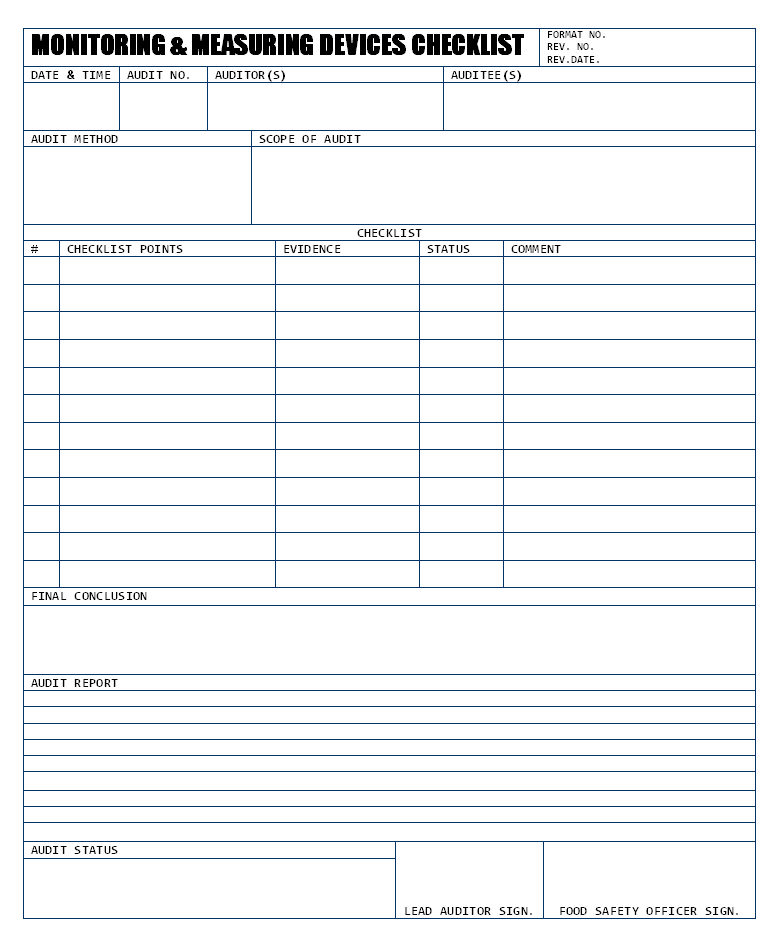

Controls of monitoring & measuring devices process is prepared & deployed in system by quality department, and quality manager is responsible to identify controlling system for monitoring and measuring devices. Monitoring and measuring devices are parts of quality system, so its important to product quality measuring system should be perform accurate & fully controlled to ensure product quality. For the controls of monitoring & measuring devices, frequently inspection / audit is conducted, generally audit is conducted monthly basis, see picture below given example format for monitoring & measuring devices control checklist for education purpose:

Monitoring & measuring devices checklist is conducted for auditing monitoring and measuring system and its supporting devices, controlling system, storage and other concern methods which is affecting quality system, some inspection points are given as below for reference:

- Whether calibration schedule has been prepared and updated for all monitoring and measuring devices? Is there calibration schedule, update information are properly maintained?

- Is there list of equipment, devices and instrument are used in monitoring and measuring processes are calibration has been checked? List is prepared?

- Verify any equipment, device or instrument which is used in monitoring and measuring processes randomly.

- Is the calibration process is conducted in-house, records are available with lab, is there calibration procedure is established & deployed? Who is verified calibration procedure?

- What is process of withdrawn of malfunctioned devices from system and how it’s maintained? Is there register / records are maintained & evident?

- Is there all the calibration processes are conducted as per standard requirements i.e. ISO 17025.

- Is there calibration technician is properly trained?

- Is there internal / external audit documents / records are available and complied all standard requirement? Is the departmental objective is monitored properly?

Control of monitoring and measuring devices processes are important part of the quality departments all procedures, documents and records are established, maintained and regularly updated by quality department, the documents are used for controlling on devices are used in quality system & the checklist is used for auditing devices to ensure quality system compliance are properly conducted during inspection processes by monitoring and measuring devices.

——————————————————————–

Download Format in Word document | Excel Sheet | PDF format

Monitoring & measuring devices checklist

——————————————————————–