Fluids line inspection process is systematic procedure help to ensure the each fluid line is install at manufacturing facility is working properly, as well piping are without any spillage or leakage.

Overview to fluids line inspection

Fluids line inspection process conduct for verification, inspection for each liquid line install at machinery, equipment, storage units etc. Where locations and areas to supporting manufacturing facility and requirements of various processes to engage with manufacturing activities. The process is verify and ensure that the each fluids line is installed properly. There is no rust, no leakage or spillage at the lines are verify and inspection is manage.

This process is conduct by maintenance team. qualified maintenance team is conducting fluids line inspection process as per frequency define by management or as type of line requirements. the Inspection process is part of maintenance tasks that inspection and its concern improvement manage by maintenance peoples.

Maintenance management is selecting some qualified inspectors for conduct the task. Hence maintenance manager is conducting monitoring, controls and reviews of this process by various ways. Visual and documentation reviews are manage on priority and frequently is important for avoiding fluids concern fire and other accidents.

Manage the priority and risk levels

The fluids lines are managed as per machinery, equipment and locations that each locations and fluids line are installation. There can be line sizes should be different so its risk level are also different. Hence the maintenance team should be manage each tasks for the inspection and risk management. To each linings should manage as per priority setup of each risk level.

The type of fluids are also important in the case of high flammable and minor or non flammable categories should be maintain and accordingly. All the inspection tasks should be manage and implement, the frequency of inspection is also maintain according to type of fluids line, risk levels and priority.

How to perform the inspection process?

Fluids line inspection process and its documentation are manage as per installation of fluids line at various places. Risk level and priority of prevent accident, maintenance team is identify priority of each fluids line. Even organize each fluids line for category & accordingly it. All the task are maintain, hence the inspection team is also verify the priority categories and risk level. To ensure that the categories, risk levels, priority and frequency of verification are implemented properly.

The use of fluids lines are install as application at appropriate requirements, each sensitive category are inspect by inspection team as on priority. The documentation of fluids line inspection processes are manage and implement by maintenance inspection team.

Fluids Line inspection format

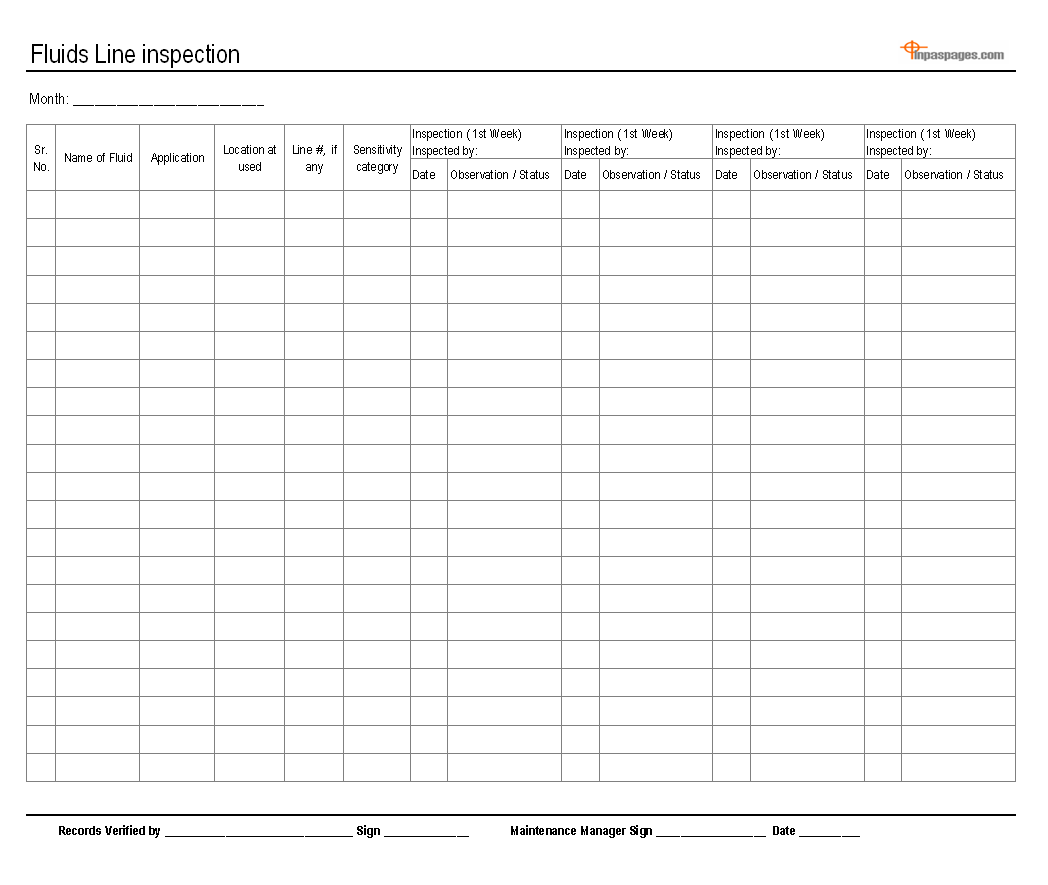

See picture below given as example format of fluids line inspection format for education purpose:

About the inspection format

Fluids line inspection format / document is use to recording information of each fluids line install in facility. As maintenance team assign duties to concern team, the team is verify the facility and manage inspection process for identify non-conformity or risk level at the place. At same the records are maintain and submit to maintenance manager for further analysis and actions on non-conformity.

Risk level and other issue identify during inspection. The documentation for fluids line inspection is important part for the risk management. That may be at the level of inspection processes, equipment for the testing and immediate actions should be needs to maintain security. The documentation are maintained as per documentation system.

—————————————————————————

Download format in word document | Excel Sheet | PDF format

Fluids line inspection

—————————————————————————