Initial process capability study carried out to determine process potentially or process is capable to given natural variation, and meets customer specifications.

Overview to process capability study

Initial process capability study is conduct by production department to ensure the process capability, variations, and potentiality of manufacturing. The study may include the entire production lines, sub-processes, manufacturing activities, resources, supporting and process materials. The study basically ensure that the natural variations and compability of processes is meeting customer specifications and end applications or not.

How initial process capability study works?

The study main conducts in manufacturing facility, to verify the primary level’s dimensional checking and verification. Normally quality engineers are verify the product dimension, to ensure that the running manufacturing processes. The outputs from the processes are use for measuring the variations, and ensure that it is giving a natural variation or controlled variation.

The controlled variations are as per customer requirements? The product tolerance is as per customer’s expectations?- if it is not that quality engineers will be conduct the process capability study.

Obviously the process potential or capability study is taken by production engineers. The engineers may ensure that processes that manage for producing materials, and procedures implementing to conducts activities in manufacturing facility are as develop, its verification depends on it.

Study plan

The initial process capability study process is conduct by production department to ensure the process capability to meet customer specific requirements, and end applications. The process potential or capability study is manage; the production manager is responsible for conducting this processes. The manager is deploy the select production engineer to verify and implementation of this process. They are equally responsible for implementation of procedures. The production engineers should prepare a initial process capability study plan, where the product information should be clearly mention. it may indicates it characteristics, specification, running quantity and frequency of study as the process handle in manufacturing facility.

Review the analysis data

The initial process capability study is manage to collecting information from various production lines. The processes to manage study, the analysis data are manage and implementation are conduct by production manager as documentation are review. The production engineers are conduct the study and prepare documents of study records and results.

Initial Process capability study Format

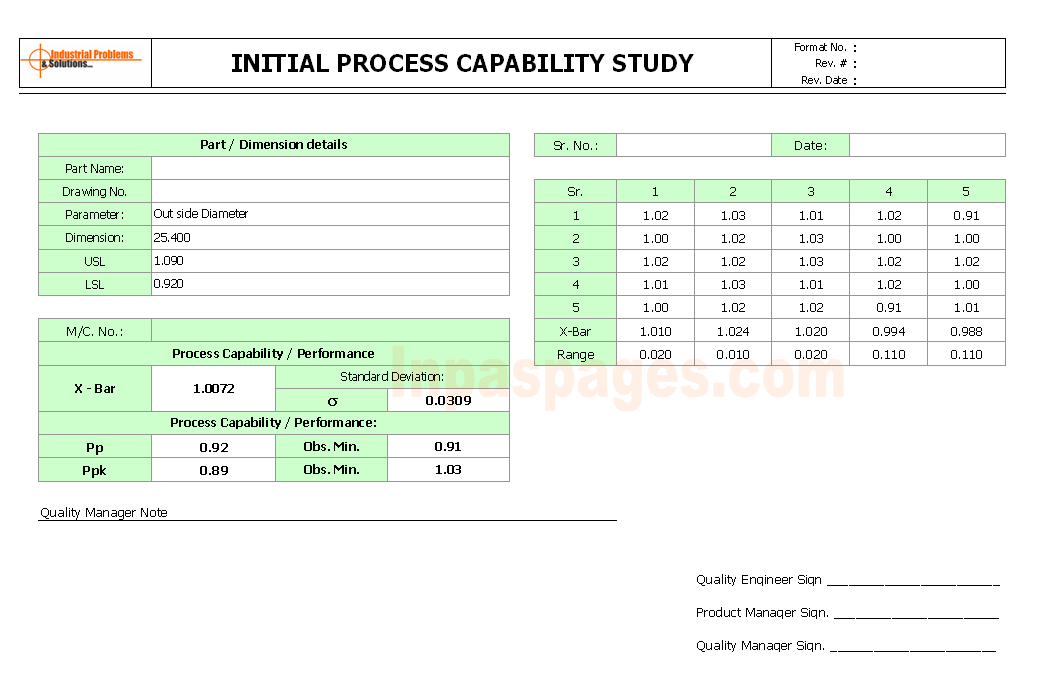

See picture below given as example format of documents that use for manage the records. The study method are used for conducting this process, below picture provide for education purpose:

Initial process capability study format is use to conducting study and analysis of collect information. These data are collect from production lines about product’s dimensions and other details. That may help for implement of manufacturing processes by conducting study and identify requirements of process improvement.

During the manufacturing processes, the production engineers should identify critical parts. The process potential, should be carried out in the process. The describe to considering product require tolerances to improve the plan to develop the process accordingly. The documentation is maintain as per documentation system.

————————————————————————-

Download format in word document | Excel Sheet | PDF format

Initial process capability study

————————————————————————-