An inspection checklist records may contain all the objectives information to maintain accurate documents and can help to track it on needs. Inspection checklist is assurance document, hence the each equipment, process, materials and / or functions may include in it.

Overview to inspection checklist record

Environment health and safety system is unique system for the industry that possible to strictly maintain the requirements of the health and safety as well as environment within the company premises which is also requirements of the government lows and factory acts of the state government.

For the maintaining the environment health and safety in plant level, timely inspection of the each locations and area as well machine and gangways too are much important, for the auditing of the plant level inspection are required the unique inspection procedure to compliance of the each area / machine and locations that is possible to reach and in right direction inspection are possible through checklist.

Checklist & EHS compliance

Checklist of the environment health and safety compliance can be fulfill if the recording of the each activities, unsafe behaviors and products are list and necessary actions are conduct. Some basic requirements of the records of the checklist that overall company checklist records can be maintain in single format that is inspection checklist records.

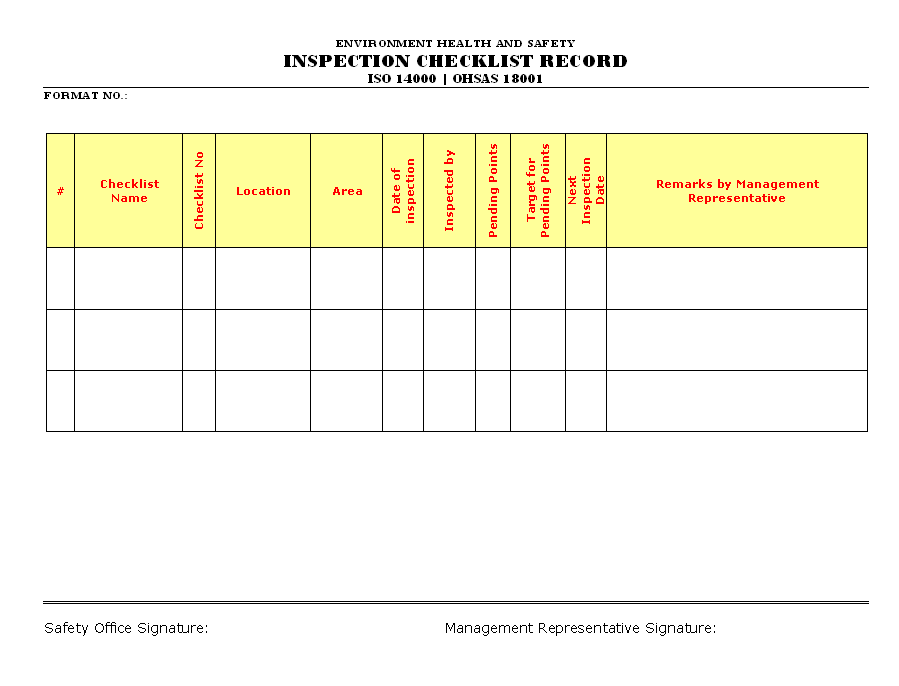

Inspection checklist record may include:

- Checklist Name – Name of the checklist are in use for the inspection area, example – Packing Area checklist, Safety equipment inspection checklist etc,. On base of the checklist name all the individual information can be get from it.

- Checklist No.

- Location – which checklist are use for.

- Area – which checklist are use for area that is part of location / department

- Date of Inspection – Inspection date is very important, reason that each inspection are pre decide. Which part of the location and area and department will be conduct for inspection. Its all depends of frequency of the inspection and management depends.

- Inspect by – name of the person who had conduct inspection process, for which date and area.

- Pending points – how many pending points are still pending that action plan or physical action are not evident.

- Target for pending points – when the pending points will be short out, ultimate date of the pending point’s completions.

- Next inspection date – when this checklist will be conduct for plant.

- Remarks – management representative of the environment health safety system, are note on the activity had conduct by the inspector. All the task are cover or not, which points is on prior etc.. Note can be write down here.

Inspection checklist record template

EXAMPLES, SAMPLES & FORMATS: Download