Inspection of packaged products

Inspection of packaged products is established and implemented to ensure packaged products for shipping is maintained quality and customer and standards requirements.

Inspection packaged products is conducted after at movement of packing of product and after the packing product, the system is established and implemented with the packaged products and packaging material to ensure packaged products are maintained quality, standard requirements and customer specific requirements which is going to shipping to customers. The system is applied at when the final quality stage is completed and material moved to packing department, at the movement final inspection which conducted for product packaging, packaging standards & assurance of quality product are fulfilled. The system is applicable to all the packaged products and packaging materials are used for shipping to customers, and the systems is also maintained for packaged materials and during the packaging processes, ensure the product is maintained its quality after the packaged materials.

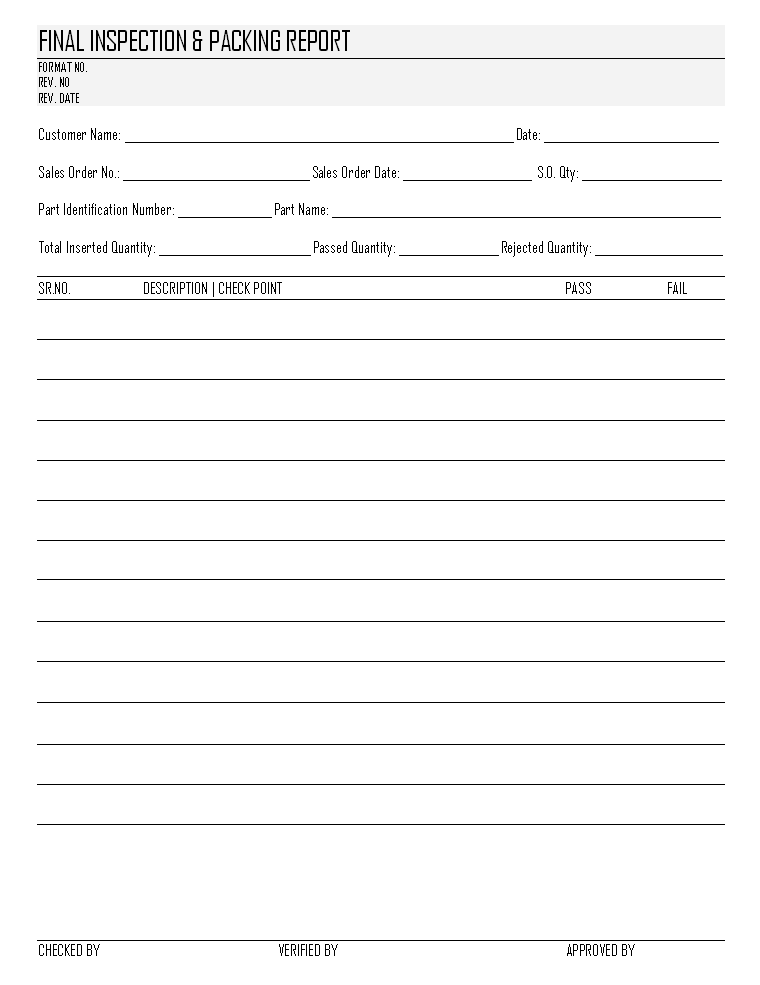

Inspection of packaged product and its inspection processes of packaging materials, during the packaging material visual, documentation and other concern monitoring, packaging materials processes. Responsible of all packing activities include loading the materials on trucks, container of packaging supervisors and packing manager. Packing concern all the activities are conducted by packing manager, when the material reach from quality to packing department, packing engineers are conducting the materials and packed as customer requirements, during the processes, quality engineers are conducting the packaging materials, packing processes and standard requirements concern packing product, and customer specific requirements. Packing inspection are conducted and recorded all the activity, visual inspected and documentations are conducted in inspection, activities are recorded in format is final inspection & Packing report which through inspection processes are conducted, see picture below given as example format of final inspection & packing report for education purpose:

Final inspection & packing report is document which is conducted along with packing processes, during inspection packing processes are conducted as per standard requirements, customer specific requirements, packaging materials are passed standard terms and requirements, material used for packaging is standards and as per customer requirements, processes are conducting properly as per standard methods etc, subjects are on priority for inspecting and on after the packaging inspection team is conducting the packaged materials as re-inspection of the documentations and visual checking of packaged material labels are staged as per products, product quantity and other product concern information are correct or not etc are verified to ensure the packaged product is correct and as per standard requirements.

———————————————————–

Download format in word document | Excel Sheet | PDF format

Final inspection & Packing report

———————————————————–