Best practices in shift handover communication of operations

Improvement best practices in shift handover communication & processes of operation to eliminate errors, accidents and enhancement of product quality.

Best practices in shift handover communication of operations in workplaces improvement, enhancement of productivity and product quality, managing communication of manufacturing’s each stages, needs to manage proper communication during shift handover process. Because of the increased rates of accidents, mistakes, errors and violation of terms of company are records are generally happened as associated with shift handovers as I personally experienced. Improvement of practices in shift handover process, management should interfere in the processes that conducting during manufacturing shift handover process, and take interest to arrangement of proper procedure to easier for peoples are conducting and being part of shift handover process, and management can develop proper procedure to improvement in best hand over procedure. Shift hand over process is directly impacting on the product quality, costing of the product, health and safety and productivity of machinery that important to proper procedure / process that helps to determine internal communications, check outs and sharing information on shift hand over processes as supervisors and concern managers.

The management is responsible for conducting, managing processes for the each manufacturing and supporting processes that management is conducting general meeting or management review meeting and discuss on points that impacting manufacturing processes and product quality concern issues, health and safety system and other mistakes and disturbances due to improper handling of communication, miscommunication, unmanaged documentation system and other systems which are general issues or reasons that maximum problems are created in the system, and shift handover process is one of the important processes where generally maximum system malfunction noted as per my experiences and review of most important records of manufacturing and supporting processes so, I personally requesting to peoples to review all the records that most important of theses best improvement of the handover processes and enhancement of practices.

Improvement of shift handover processes and best practices needs to verification, reviews history records to easier for identify requirements of improvement in the system, there some basics are needs to used, like use checklist for verification of the processes during shift handover. In the checklist all the required processes needs during shift handover are managed and mentioned in checklist that easier for supervisor to conducted and managed without forget or miss points which is important for next schedule or shift to managing and arrangement of the manufacturing processes, arrangement / managing manpower and machinery. And on base of the reviews of historical records, management can identify best / successful handover procedure followed by any supervisor can be make as template for others, and improvement of the system where generally errors and mistakes, accident or malfunctioning are occurred. The analysis of the shift handover concerning processes, data migrations from various department and locations are important ways to managing and improvement analysis structure to identify accidents and error rates in the manufacturing processes and supporting processes which is happened in shift handover processes, the best practices improvement are manage and conducted accordingly on analysis results and processes amendment.

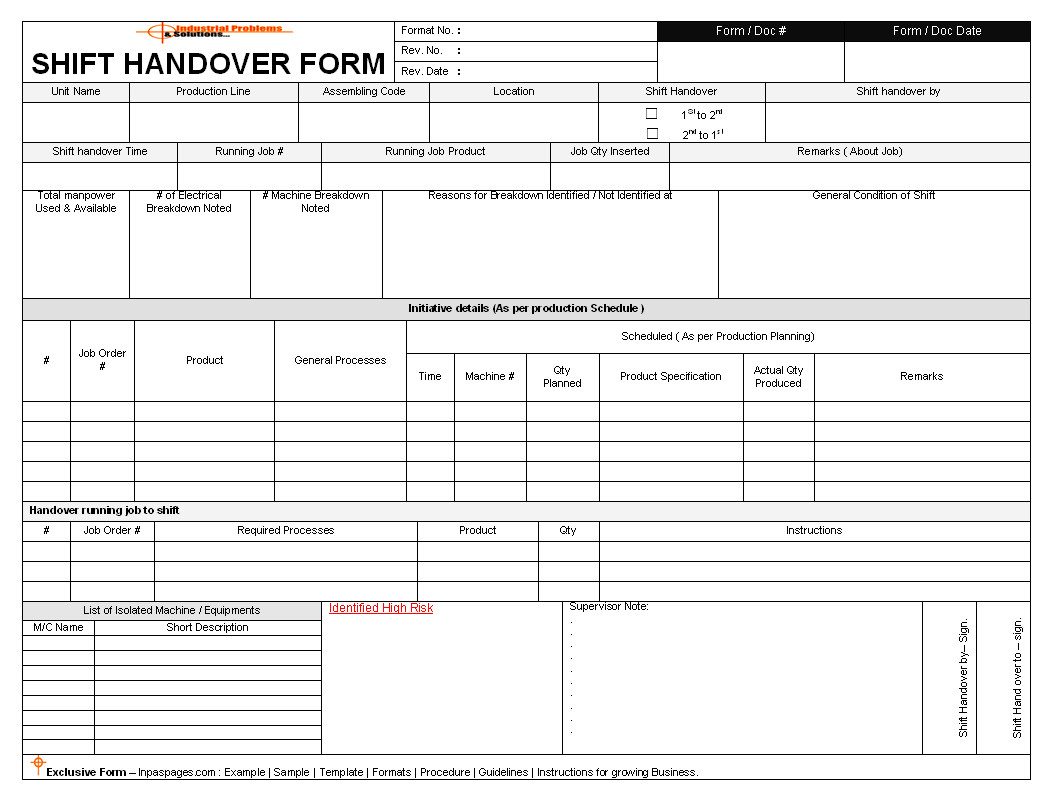

The best communication practice is meeting on shift handover of both the supervisors, the face to face meeting is best idea for managing records, conditions of the shift, production and utilization in during previous shift can explain by supervisor who is leaving shift, because the best guideline can possible on face to face communications, sharing documentation and aware the condition of previous shift, there are so many general and important communications, points are needs to conducting in the meetings where safety, errors, isolated machinery and equipment and reasons behind it, problems occurred during previous shift etc.. are important and most important is the risk identified during the shift and needs to take immediate actions are shared by shift supervisor who is going to leave shift and hand over to second one. There are also important that outgoing supervisor is provide all documents and records to incoming supervisor to easier for understand situation of production processes and manufacturing condition, risks and safety requirements. see picture below given as example format of the shift hand over form which is filled by outgoing supervisor and provides to incoming supervisor where all required information filled and aware the details are mentioned in form, below form given for education purpose:

Shift handover form is the structured written format that used by outgoing supervisor for acknowledgement, aware the situation of manufacturing processes, running conditions, isolated system and risk are identified etc., are general points which is needs to know for incoming supervisor, the document is introducing important materials to incoming supervisor that helpful for conducting each task that perform in shift and easier for the reduction of risk level that information and points that helpful for the reduction are mentioned or suggested to incoming supervisor.

——————————————————————————-

Download format in word document | Excel Sheet | PDF format

Shift handover form

——————————————————————————-

Related: