A product release checklist covering all activities that may related to update of product technical specifications and its version. It may also include the base performing activities such as engineering, manufacturing, marketing, sales, product support and functions etc.

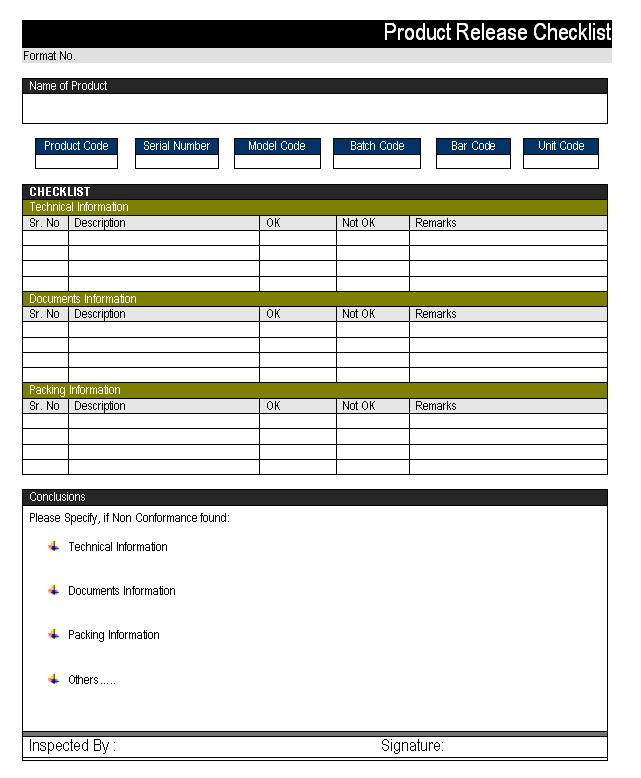

Product Release Checklist

Overview to product release checklist

The purpose of the product release process or by using product release procedure, the supplier meant to prove that all product requirements are comply and fulfill with customer are met.

This process should be implement to the all manufacturing activities and products including raw materials, semi-finish product and bill of materials use during producing or finalize product, and all the service. Which includes in manufacturing processes.

The product release is involving the activities like assessment of production processes that is performance using related documents, records and production samples to ensure that the conditions / preconditions for batch production of products conforming with standards and specifications are met.

On before the initiation of production, the sampling processes are conduct before the full production operations are run, the supplier should assess the sample testing and verification at its facility. To ensure suitability of the production processes to manufacturer the product accordingly to quality requirement, technical requirements and end application requirement of the customer.

The customer should agree the production capacity for prescribe period of the time or to provide the services must be determine with trail production run for producing the customer require materials.

When use this checklist?

When the product is ready for the dispatch, all the concern information, technical details after the quality passing, final checklist are need to check out all the concern information, material conditions and packing. To ensure the all the details and condition is as per requirements. When the quality inspection doc auditing, very first check out all the technical details, technical details are very important for the material, seconding documents audit and packing concern audit.

Where label conditions, information, product codes, all the require codes, manufacturing date etc.. important information are need to audit

- Name of product

- Product Code

- Serial Number

- Model Code

- Batch Code

- bar code

- Unit code

- Checklist

- Technical information checklist

- Documents information checklist

- packing information checklist

- conclusions

As you can see above information is sample, example fields can have use for the product release checklist for after final inspection checking by quality department.

How to maintain the records?

The documentation of the production samples and its inspection on initial production should conduct and its reports must prove supplier end, the supplier should have submit inspection results, all the functions and features of product to meet the customer requirements and standards. Hence in the documentation, the sketches, drawing should including related technical delivery condition and specifications mention. In case any deviation identify that must be clearly mention in the inspection report. The documentation of initial production sample should approvals from customers for further actions.

EXAMPLES, SAMPLES & FORMATS: Download

Related: