Product repair and rework process

Product repair and rework process is describe procedure or guideline to maintain system activities and documented procedure to conducting product repair and rework activity.

The procedure or process for the product repair and rework in manufacturing, production processes to provides systematic guideline or instruction for the product repair or rework processes are conducted, to establishment and maintain a documented procedure for the production processes and update information through best practice for the instructing the peoples of production for awareness & maintaining requirements of the procedures of product repair and reworks, the processes is conducting by the production department that each manufacturing stages, processes and processes owners are needed to follow the documented procedure, product repair and rework analysis and its implementation needs are manage by the concern department.

All established manufacturing processes, instructions and concern guidelines are conducted for the producing the materials, during the processes / manufacturing processes in case any product non conformity identified, or the material / product is delivered to customer and at the customer end any non conformity identified that the manufacturing unit should take the actions on the comply requirements of the product non conformity solutions. The procedure helps to identified non conformity and its concern compliance to meet the product specification and standard, technical requirements of product. Management taken the actions for evaluation of non conformed product to identify root cause of non conformity to reach at source of defect in the product that should be unique root cause need to identify and implement for the product conformity. Management is conducting the manufacturing process and its concern supporting activities for the product repair or taken in re-manufacturing process for re-works activities.

Procedure for product repair and re-works are established by the management with contribution of concern departments, all the manufacturing activities, processes and supporting activities including machinery and equipment activities to the understand and manage the requirements of product repair or re-works processes to comply requirements of product standards. All raised non conformity concern product that should required to identify source of defect of product i.e. non conformity source to eliminate possibilities as the impacts with other areas and product manufacturing. Quality engineers / quality control department shall be responsible for established procedure follows and conducting product for repair or re-works, quality team shall reporting to management for the action plan and report for the requirements of further processing to met the requirements of product standards.

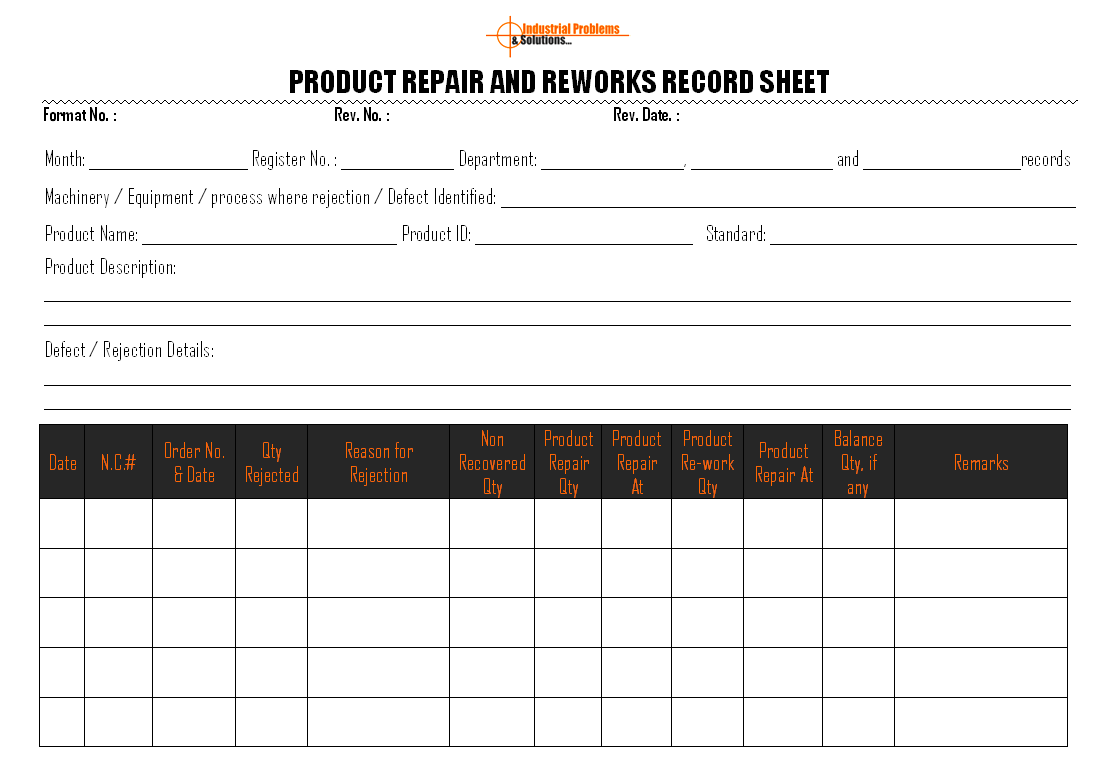

The materials which are identified as non conformity that should need to segregate by the concern department, during the manufacturing process, due to machinery errors, equipment defects, raw material defects or any manufacturing processes cause rejection of the materials that all the materials are conducted and storage separately. The materials / product are conducted for the re-work or repair process that should be required to maintain standard requirements / technical requirement of the product, in the manufacturing activities the materials is maintained with rejected materials at all the stages of operations as per standard operating system / instruction given by management for the non conformed product storage, handling and movement. All the product having a non conformity are conducted separately and records for the product repair and re-works are maintained separately for the system & costing effects at end of the month, manufacturing activities costing is effecting due to repair and re-works process that impact of the standard process implementation is conducted and its sequences are maintained by the management interface. See picture below for the reference of the product repair and re-works record sheet as below:

The records of product repair and reworks in the manufacturing, processing unit for analysis to identify source of defects are occurred that can be raw material defects and moved without proper inspection, during material handing at any stage, material properties, due to defective machinery or equipment or due to processes that are need to proper identify and action plan for the improvement concern causes to eliminate possibilities in the next orders as impacts of analysis. Product repair and rework records are helps to analysis processes for the improvement in the manufacturing and concern supporting process system so its very important to management consider the records for the analysis and its also care that all records are properly handled during the process rejection identified.

General process of product repair and reworks

- From manufacturing processes, supporting process or due to defective machinery, equipments caused nonconforming materials during the production stages and operations should be handled as per guideline / procedure of the product repair and rework to proper monitoring, controls and deployment of actions on it. The entire non conforming product should be controlled.

- The instructions / procedures should be maintained for nonconforming product, which can be for product repair or product reworks and should be move as per procedure.

- During the manufacturing processes, supporting process or during any operation the material is identified nonconformity that should the material should be proper segregated, labeled and identified for the storage as rejection quantity / parts that will be for repair, reworks or scrap.

- In the given treatment of product repair or product re-works, all product or materials should be proper quality inspected and identified standards are match to required customer’s end application.

Product repair and reworks process is contribution process of the manufacturing units that all the department, operations and project peoples are need to follows & implement as and when required. All concern records of product repair and reworks are maintained properly for the implementation, analysis and for financial activities. Financial team is also conducting information, records from production to calculate cost of the product individually hence the product repair and rework records is controlled by management to various actions.

———————————————————————

Download format in word document | excel sheet | PDF format

Product repair and reworks record sheet in word document

———————————————————————