Product deviation / policy deviation

Product deviation / policy deviation is difference of the product or policy with standard product requirements or standards policy defined by management.

Product deviation is the non conformity of the product which is manufactured, produced as per standards but the minor or non acceptance level is unmatched requirements of end applications or customer technical requirements. Product deviation is occurrence of considerable tolerances and customer required technical requirements are unmatched or non compliance is deviation of product, hence policy deviation is violation of the consideration policy requirements by minor or considerable values are non confirmed is policy deviation.

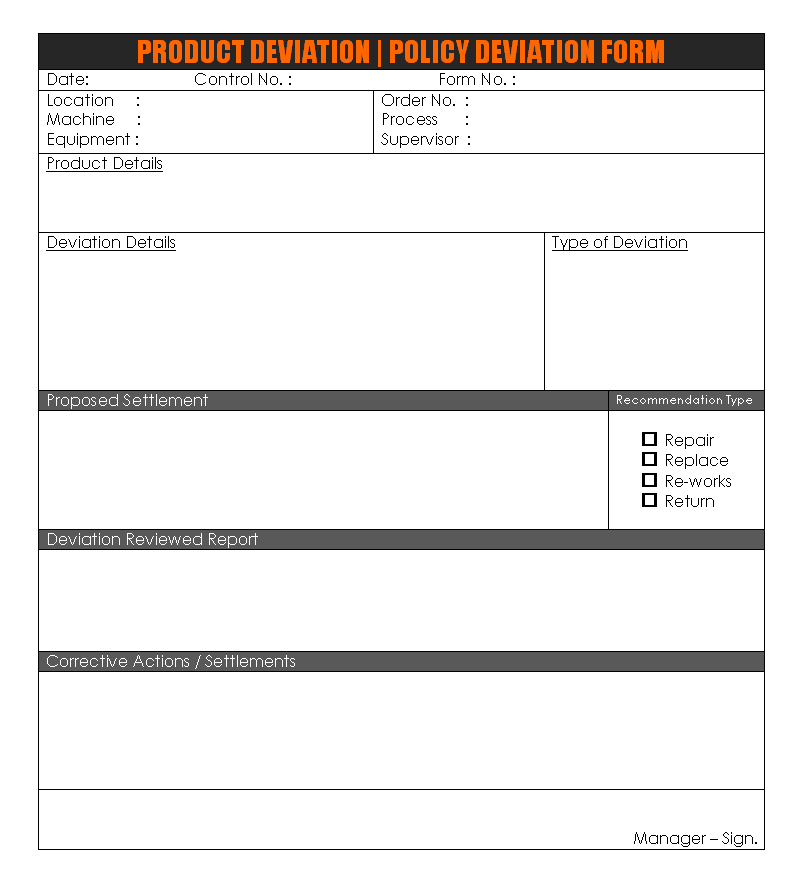

Product deviation / policy deviation occurs in the manufacturing processes, production line that requires to action by concern peoples to identify source of the deviations, reasons of deviations, substitution requirements of processes to minimize possibilities of deviations. The product or policy deviation are considered on product, policy deviation form that should completed on deviation occurred, see below picture for reference of product deviation / policy deviation form:

Product deviation / policy deviation form, before product settlements, adjustment or policy deviation is considered for the recording and further action purpose. The responsible personnel considered submitted product deviation / policy deviation form and evaluate the subject to confirm that the issues are raised and causes of the potential deviations are due to some reasons like, damage resulting improper handling of the materials, damage or defects due to manufacturing processes failures or sequences, damage or defects or deviations due to defective machinery, equipment used in the processes or any other reasons, the results of deviation imperfections in accordance with product / policy standards. On base of the product / policy deviations and identified cause, occurred deviations need to proper action plan by the management and concern department, the detailed information, reasons and possibilities of the recovery is depended for the deviation occurred, in case the material is not recoverable that need to final settlement with customer in case the material is delivered to customers or product will be internally released for the deviation solutions.

The impacts of the product deviation / policy deviations in the manufacturing units and a customer had received the materials with the deviations that need to return credit to resolve the issues against the deviation occurred, in case the deviation is possible to solve by the further processes, reworks or any other ways are conducted to save the claims issues. The damage / mistakes or errors due to deviations, processes, machinery or equipment concern issues and cause deviations are analyze by the team to improve the concern areas where deviation root cause identified for the improvement and impact the locations for the effective implementation for the same.

——————————————————————-

Download Format in Word document | Excel Sheet | PDF format

Product Deviation / Policy Deviation form

——————————————————————-