Production lines input fulfillment

Production line input fulfillment process is conducted to managing production required inputs for producing materials are managed accordingly.

Production line input fulfillment process is established for management of each production requirements, bill of materials, stock of raw materials required to loading at production lines, machinery needs the raw materials for producing materials, and the requirements of inputs for the each production lines are managed in the process. Production lines input requirements are managed as per customer product requirements, technical and specification of product, hence production regular bill of materials, resources that used in manufacturing processes are managed, the raw materials requirements for each machine and production lines handled as per customer order, machine speed & cycle time and the stock at the processes and supporting materials input requirements are managed in manufacturing, production input fulfillment processes. Production line input fulfillment process is managed by concern supervisors hence production manager is establish this procedure for managing each requirements, resources and planning for input fulfillment at each level and process stage in manufacturing facilities. The production lines input fulfillment process is managed as per standard requirements of production lines, the standard requirements, specifications, and technical requirements of customer are considered, and the materials are stocked, bill of materials, resources are managed as input fulfillment.

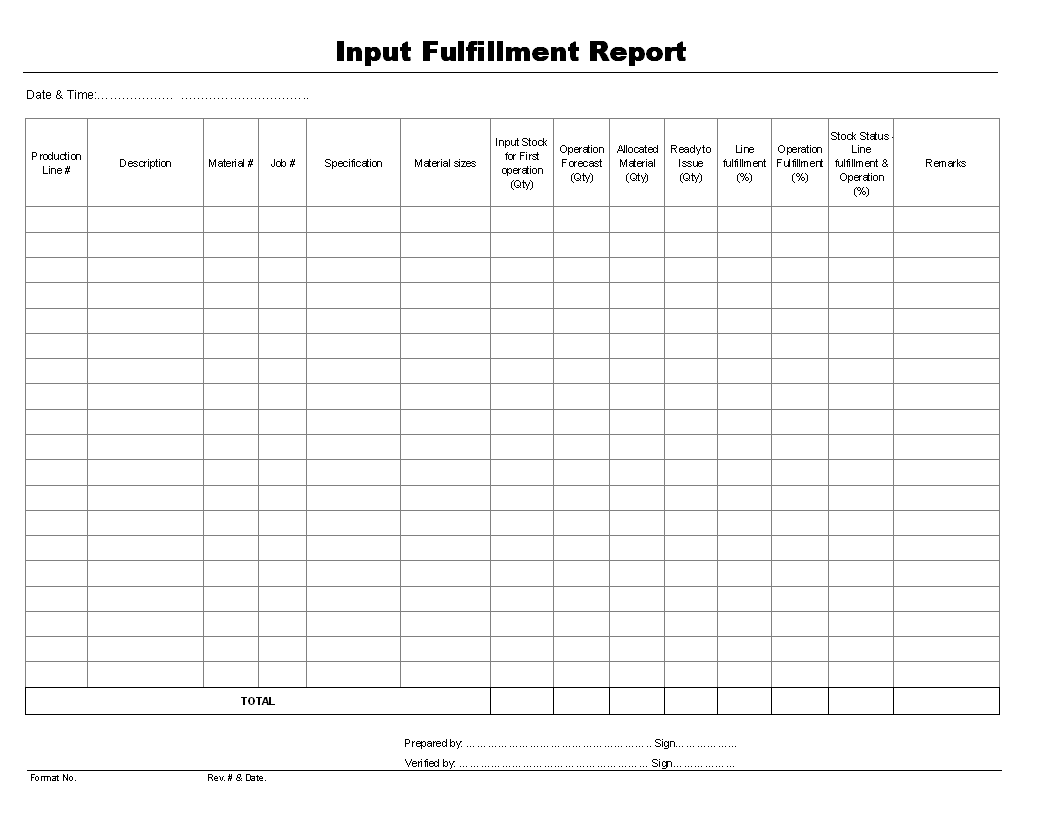

Production line input fulfillment process is managed and verified by production manager, production manager is responsible monitoring and controls over process to ensure that requirements of production lines, resources management and deployment of materials are handled and all required inputs are fulfilled. The production lines input fulfillment is part of planning and its actions are managed as compliance of planning, once inputs are deployed at required locations that is fulfilled of inputs and the required cycle is completed. The process is managed, and its required documentation are handled by concern supervisors, hence production manger is responsible for verification and reviews the documents as per frequency, The reporting of input fulfillment is conducted by production managers for analysis information collected from various department, locations in production lines. See picture below given as example format of production line input fulfillment sheet for education purpose:

Input fulfillment report format is used for recording information of production lines requirement that is machinery requirements, raw materials requirements, bill of materials that used during processing and stage wise requirements, resources that managed for producing materials, and stock of the materials that needs for next processes are pre-stocked at the location is important part of input fulfillment in production lines that supervisors and concern authority are managing activities accordingly & considering to the materials should be at the location in stock to minimize change over time, material handling time and loading time at machine to complete cycle in minimum time with limited resources.

—————————————————————————-

Download format in word document | Excel Sheet | PDF format

Input fulfillment Report

—————————————————————————-