Reorder level: Calculation | Affected factors/ Reorder level Format for Consumable Goods/ Critical Spare parts

What is reorder level?

Reorder level or Reorder point is measurement of stock level, which suggests when to give new orders so that the minimum level of stock is maintained. Standard Calculation of Reorder level = Lead time in Days X Daily average usage. Where the leading time is that it takes the supplier to provide the demanded quantity.

How to calculate reorder level?

An amount of the materials is needs to maintain at its minimum level which is defined as “reorder level”. Its formula is:

Reorder Level = Lead Time in Days × Daily Average Usage + emergency stock (Aka Safety stock)

Example:

At any store department in organization, knows the daily uses of any particular item. Store personnel needs to maintain any particular item such as cutter of wheels. Cutter of wheels are daily used is 5, from different departments with same size. Hence, if store want to calculate weekly “reorder level” of cutter of wheel, they will calculate as below:

Reorder level = 5 nos. x 7 days = 35 nos.

In case department want to maintain emergency stock, at least of 5 days to maintain of cutter of wheel, they will calculate:

Reorder level = 35 Nos. (Regular reorder level) + 25 nos. (5 nos. x 5 days) = 60 Nos.

These is only single site example the see as above. But there are one or more factors may be including for decide “reorder level”. The management also consider some points which directly effects on inventory as you can see in next point.

How to decide reorder level?

Reorder level are maintained on base of the stock of the materials all the major factors of the level should be maintains and decided on base of:

- User Department current requirements

- Previous data, Analysis of last six months’ data / Three months

- Critical Spare Parts to needs on emergency

- Distance of Suppliers locations

Factors that effects on inventory

Reorder level is deciding on base of the stock ratio, criticality and effected factors. All the major factors inpaspages.com identified, that affects the stock levels and its decisions are as below:

- Some Critical Parts are required on urgent basis that can cause the shutdown the machine & enable to maintenance in case of material are not reach at time to time to repairers.

- in case of the material are comes from the long distance that take the long time to reach at the destination, that can cause the major impacts on the maintenance & also affect current projects.

- If the reorder levels are not maintaining that on urgent requirements possible that high rates are pays & premium freights too.

- Inventory Turnover ratio is one of the effective tools that need to care for the maintained in store department, in case of the reorder level are not established that ITR implementations not easy to proceed.

- Moral of the maintenance team can possible fall down on late material deliver at spot.

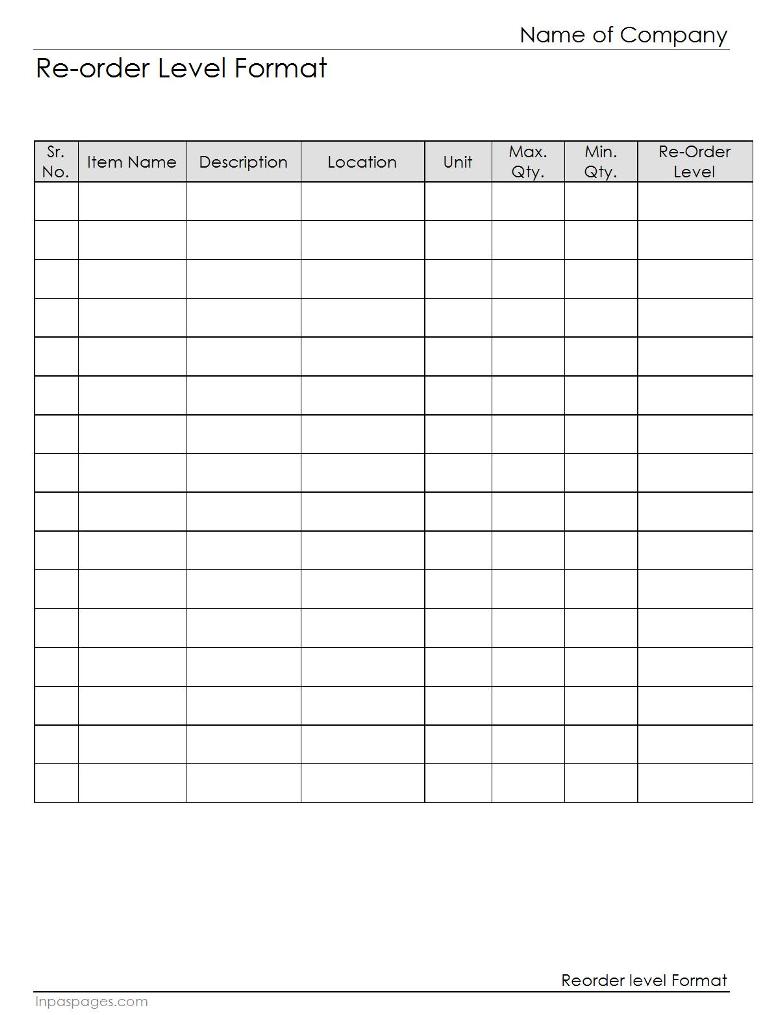

Reorder level is one of the most important tool that used for the maintain inventory. It will help to increase reliability and cost effective management. Here simple format is available for instant start over your inventory as below: