Risk identification in workplace and assessment

Risk Identification and assessment is the process to identification and controls over risk in workplace to deploy controls to eliminate.

Risk identification and assessment is the process or procedure to identify potential risk in workplace and by proper controls over the risk and sources of risk to eliminate the risks or minimize level or risk in the workplace. In the workplace various processes are required to producing material to support of manufacturing processes, supporting processes, heavy equipment and machinery are deployed, so it’s required proper analysis for identification risk from the machinery, equipment and processes. Workplace is fully equipped by manufacturing machinery, equipment and various processes for manufacturing activities but the heavy equipment and machinery having a risks that needs to proper analysis of the each activities and its sub activities, processes and its concern supporting activities, machinery, equipment and bill of materials with the manpower behavior analysis to identify risk on subjects, all the potential risk are identified and ranking to proper controls over it.

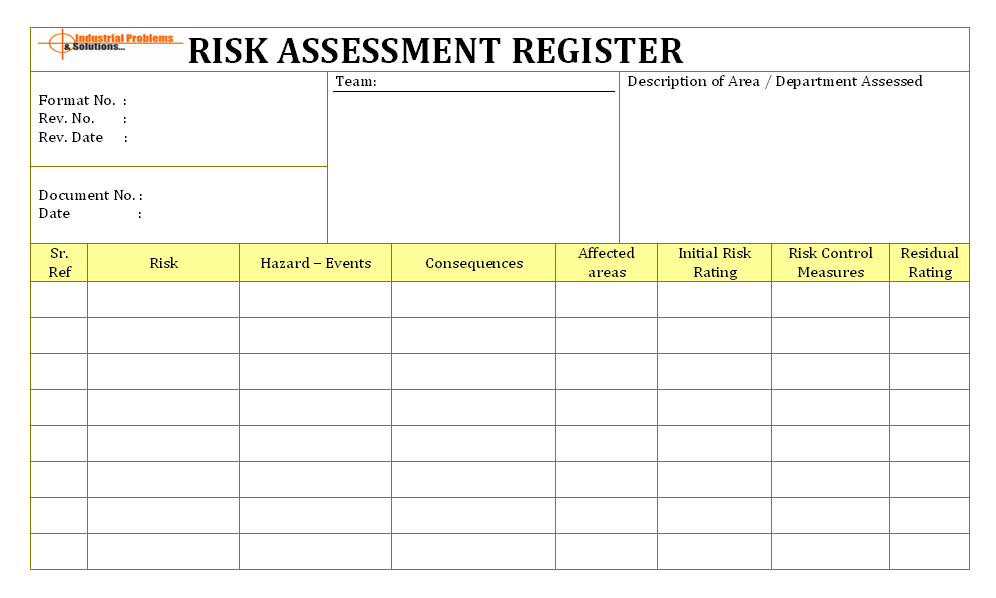

Risk assessment process is contribution of the peoples are working in workplace, during the risk identification management arrange meeting with bottom level to top level of members of department to discussion on all the process activities, regular habits, reliability of equipment and machinery and other concern department issues are discussed for identify risk during the workplace. On the identification of the risk within department, all the identified risk are proper raking are arrange to manage priority high to low level, in case any risk are identified as the high level that all potential risk are need to immediate and proper controls. See picture below how to risk are manage for the ranking in the register for the proper controls are defined:

All the identified risk are manage in the sequences of the high level to low level for the deployment of controls there several ways that possible to control the risk;

- Eliminate process where the risk is identify and not possible to remove form process that eliminate risk from system.

- Engineering controls is one of the best possible ways to eliminate or minimize risk level in the system; generally in the risk assessment system management’s first choice is engineering control through controls on risk level.

- In case any material having conform risk that management needs to control by the substitute materials for the controls, substitute materials should be also need to proper ranked and analyzed to ensure the risk should be minimize or eliminated.

Only deployment of the control measures and control over the risk on high leveled identified risk is not enough, for the continual improvement in the workplace and processes that need to each identified risk and its proper assessment is required to provide safe working environment and needs management commitment for the same in the workplace.

—————————————————————–

Download format in Word document | Excel Sheet | PDF format

Download Risk assessment Register

—————————————————————–