A Lean implementation plan is a systematic process planning to improve process efficiency by enhance productivity of resources and even controlled cost.

Overview to lean implementation plan

Lean implementation plan is systematic process planning of manufacturing activities. The activities may contain supporting facilities, testing plan, floor management, procurement and consumption etc., The processes are integrated lean planning are helps to improve the overall efficiency of manufacturing. That is process efficiency at any level by organize the system’s parts to improve productivity of each resource engaged with manufacturing. Even with the supporting processes in fully controlled costing management.

The lean manufacturing is part of lean management that here we conduct floor management part that help to internal departmental as well as ground level implementation of resources. As well activities managed for producing materials or as supporting to finalize materials to provides quality materials to customers.

How to proceeding plan?

The lean implementation plan process is maintain in production lines even and also at various levels and workplaces. To identify overall improvement by involved lean planning. The lean planning and its processes are conducted by merged regular processes or its amendment of existing system by adding lean processes requirements in regular tasks.

The plans may prepare by selective leaders for particular tasks, locations or overall process improvement. The lean leader is conducting planning tasks to supporting of lean team. The lean team may selected best experienced, and skilled personnel from various departments. The motive can be implementation of lean system in organization.

The planning is manage with step by step implementation in existing locations, where manufacturing processes and its supporting processes are conducting and engage for production. The team leader is define the requirements of implementation, prepared planning location wise, process wise.

It can be possible to identify improvement opportunity at targets locations by analysis the regular tasks. That can various processes are conduct and during the observation identify opportunity and possibility of improvement in processes. To achieve targets for cost controls, productivity improvement.

Targeting areas for implementation

In the lean implementation planning is conducts for major three things that needs that is targets for the implementation processes are conduct. The team is focus on the base opportunity to implement the processes of lean requirements. it may define processes and overall implementation planning at various locations as per plans and schedules for target locations and its concern processes.

The implementation are targeting or condition the expecting at implementation areas are:

- Improvement in manufacturing and supporting processes efficiency

- Overall improvement of productivity of resources engaged with regular tasks i.e. manufacturing processes and supporting processes.

- Fully controlled on the activities to minimize / reduce the cost of each resources including process costs.

The above targets are in middle of planning should be highly appreciate, if the planning may consider. As well level of implementation are too. The lean concept is huge where all minor activities are properly detail and implement by clear vision of lean management.

Lean implementation plan format

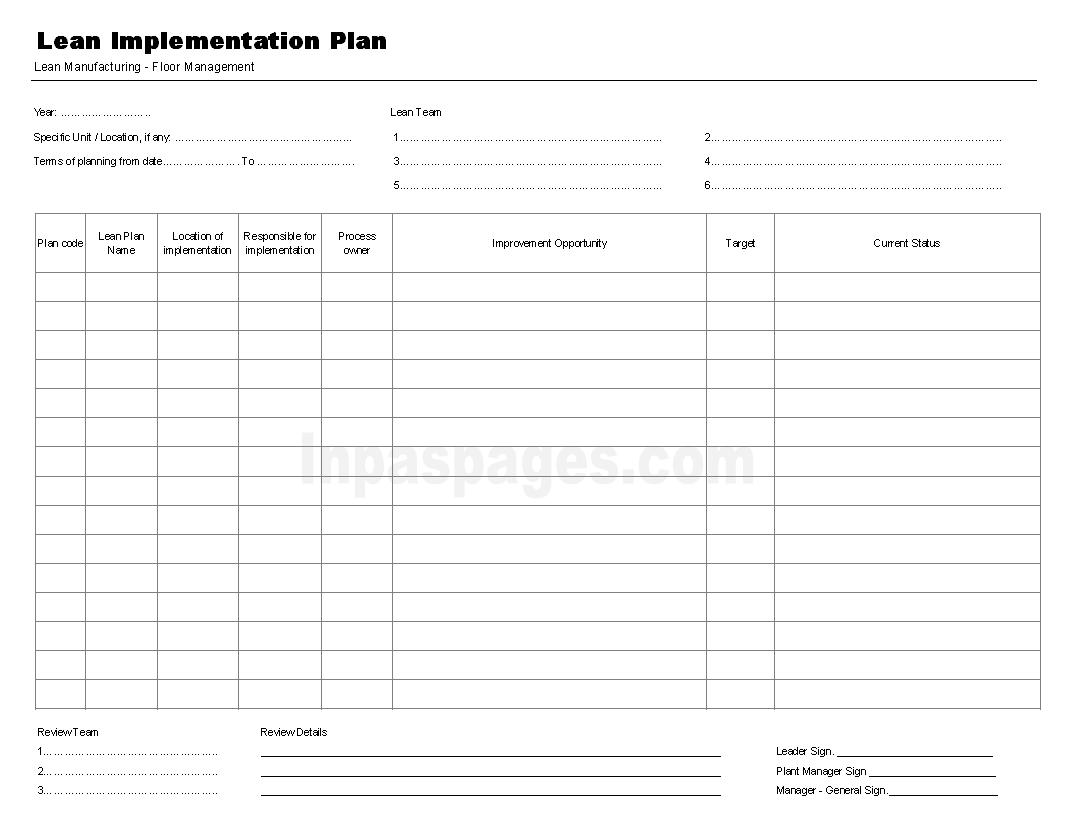

The documentation for the lean implementation planning is maintain requirements. See picture example format of lean implementation plan. The planning documentation are base of implementation. Here provided for education purpose:

About Lean planing documentation

Lean implementation plan format manage in organization for improvement parts in various levels. as well locations and in various processes. The lean implementation plan format is use to recording planning processes defined by lean team leader for improvement. The lean planning is identify on plan code where all the stage wise planning and its implementation is manage. It may by location wise, and / or process wise.

The team leader is assign duties to concern peoples & define responsibility for particular improvement planning part. At same the process is handle for each planning part. The documentation for lean implementation is manage and according all the concern process is manage.

————————————————————————-

Download format in word document | Excel Sheet | PDF format

Lean implementation plan

————————————————————————-