Safety Lock out / Tag out Process for Maintenance task

Safety lockout / tag out process implement to control potential hazardous stuff released by energy sources during serving & maintenance of equipment.

Safety lock out / tag out program or procedures are established, maintain and updated to control the energy or released of hazardous substances during regular activities from the equipment, machinery or supporting plantation areas, the safety lock out / tag out process for the prevents injury, emergency resulted from unexpected released energy form equipment by accidentally. The purpose of safety lock out / tag out for the internal regular / management system by guidelines, instructions & procedures for ensuring equipment are inaccessible from all potentially hazardous energy sources.

Safety lock out / tag out process can applied to all machinery, equipment, electrical controls etc., for maintenance & serving regular activities, energy sources storage the energy or pass the energy that can released during the operations that causes injury and create emergency to isolate the possibility this process helps to control over it.

For the procedures establishment, maintain and updates for the safety lockout / tag out is of maintenance, all the responsibilities for ensuring safety of the working environment for lock out /tag out procedures implementation, verification and effectively apply. In the approved process of safety lock out / tag out are not changes by personnel without authorities approvals, management preventative of safety & maintenance managers’ join authorities can approvals, changes made & apply.

Energy sources is fuel for the machinery, equipment, processes such as electricity, gas, liquids, water, steam etc.. Which is form of energy operates or support to machinery, equipment or processes. The safety lock out / tag out process also focus on stored energy like rations, gravity, mechanical energy, thermal energy, hydraulics, pneumatic, refrigerant are form of stored energy, motive of the safety lock out / tag out process is controls on unexpected energizing.

| Sources of Hazardous Energy | |||

|---|---|---|---|

| Electrical | Gas | Water | Hydraulic |

| Pneumatic | Thermal | Chemical | Mechanical |

| Refrigerant | Radiation | Gravity | Pressure |

Why Required Safety Lockout / Tag out?

- Safety Lock out / tag out process is required to control over hazardous stuff released from unexpected energizing by energy equipment, machinery & energy lines cause personal injury and emergency. Energy stored, pass from equipment or dangerous materials passed from equipment can released accidentally during the operations, maintenance are need to isolated before emergency, safety lock out / tag out helps to controls on dangerous materials to released in any form.

- Some activities are necessary to maintain equipment through cleaning, lubrication, inspection, auditing, repairing, setting etc.., needs to conduct periodically, during the operations safety of the peoples are maintained by safety lockout /tag out process.

Performing Safety Lock out / Tag out Process

Equipment / Machinery will be locked out under the requirements of whenever works are in progress on the machinery, equipment & machine is operated that possible cause of accident that required lock out process & also continued operation of the machine / equipment cause damage. During the operation line installation, maintenance, adjustment & process maintenance of any equipment process that stored energy released suddenly be cause injury or personal emergency, so during the operations lockout / tag out should be performed.

- All the affected personnel should lockout / tag out system is in system should notify, Authorized personnel must aware types of the reasons, level of energy that machine / equipment operations, utilizations & hazards identify, priority performance of lock out / tag out conducted by shutdown all running controllers.

- If the machine / equipment is in used, operating that needs to shutdown as normal conditions with disconnects switches, powers & other connections to perform any maintenance activities. There also need to ensure that main power switch is OFF position to isolate the machine / equipment, engineers should check the stored energy for dissipated to perform task.

- Lock out / tag out devices to each energy isolation on machine / equipment are apply by only authorized person, whole procedures are conducted by safety precautions & conditions are defined for installations, wherever lock out / tag out procedure are conducted there should be particular indicative color tags available, wherever tag is available mean all the regular operations are not performed by any employee, its means under maintenances or isolated energy for prohibited to be operated.

- On completion of maintenance task & before the released or operating energy from resources to machine / equipment system, the authorized person will inspect to ensure system condition & after removes lock out / tag out devices.

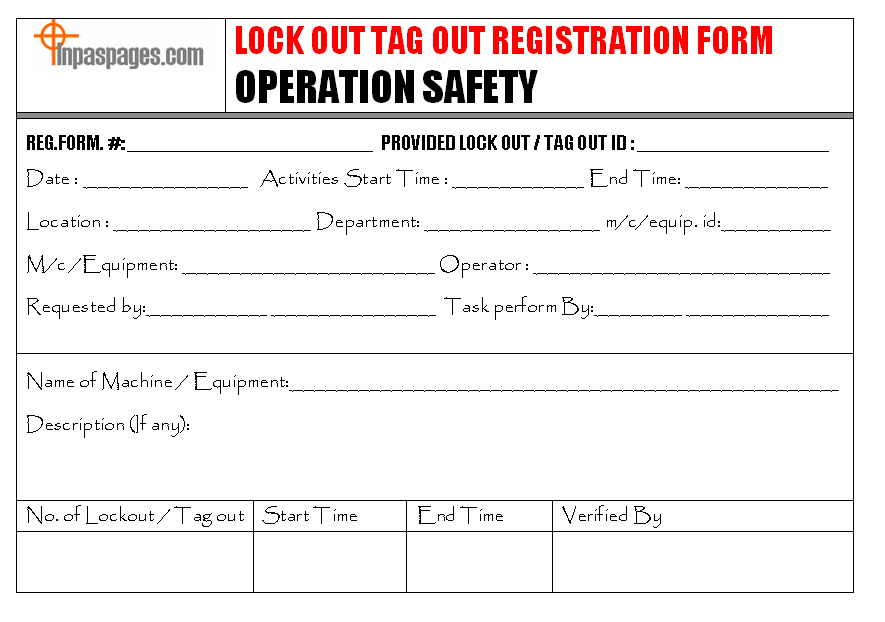

Lockout / tag out process is conducted with special devices having includes special keys & lock supports the system to proper lockout and special defined tags are used as per company guidelines. Whenever lockout / tag out process are conduct at any machinery / equipment or control panels that ensure its should center locked, the process will be start by special formatting / documentation system that helps to recording information of the startup activities. When the company / individual authorized personal is going to perform lock out / tag out that needs to document information in the operation registration form for lock out / tag out to information / records are maintain, update to ensure system is properly conducted. See picture below for Lock out tag out registration form for operation performance:

The completion of the operational safety registration – lock out / tag out registration for operational safety task are conducted by concern peoples, simply the lock should be well know locks to all the plants peoples that understand lock out / tag out process are ongoing, further keep the unique key which no master key for the lock of lock out /tag out.

Each lock out / tag out procedures are conducted by trained peoples, authorized personnel must knowledge to carry out all the contents of the process, All peoples should be trained on process of lock out / tag out to makes a competent to identify risk in lockout / tag out process. Before the act at the plant, all the lock out /tag out process are demonstrating during the training.

—————————————————————————–

DOWNLOAD FORMAT IN WORD | EXCEL | PDF

DOWNLAOD LOCK OUT / TAG OUT REGISTRATION FORM

—————————————————————————–