A stacking inspection process is material handling & storage process, to ensure the design and stack articles consider safety requirements and manage as standards and sustain formats.

Overview to stacking inspection process

Stacking inspection process establishment needs to identify all the standard requirements for article stacking and organize. To ensure the all stack materials are manage safety concern requirements, and follow the standard system procedures during stacking. On as stack materials / articles are proceed standards to eliminate possibility of incident, maintained material quality and well organize & structural material stack.

To easier for removing and further stacking as sustainable formats. The stacking inspection process is conduct by qualified inspectors on as frequency define. Verification and inspection of each locations where stacking process is conduct. All the procedures are maintain as per type of material stack. Its concern the materials inspection priority for inspection and auditing those areas, like high flammable materials stacking needs frequently monitoring and inspection to determine control by define control measures to avoiding incident at appropriate places.

How to conduct Stacking Inspection process

The purpose of the stacking inspection process is to ensure the at all the places where materials / articles are stack and maintain is appropriate requirements. As the general system requirements are safety concern requirements, environmental requirements, stack material quality. Movement friendly stacking system and easier for further stacking and removing at each place where materials are stack.

Hence the stacking materials should be manage maximum stacking limits and those limits should maintain at each unit. The locations where all safety precautions should verify & aware the peoples working around it. The training, awareness programs & accuracy of each movement should be verify and inspected as needs.

The stacking inspection is prime requirements for assurance of safety, product quality, systematic stacking and documentation of applicable places. The design personnel are conduct the inspection process, safety officer is prime responsible for managing tasks for stacking inspection where quality team, safety officer and management representative of integrate management system.

Implementing the process

It is prime responsible for identify requirements of inspection processes, establish inspection require procedures, guidelines and instructions for inspections and assignment of duties and responsibility to select personnel for inspection process.

The designate personnel are responsible to do inspections at the prescribe intervals, and select places where material stack.

On the change of places, order of stack locations needs to inspect materials at approve intervals or more frequently as may be necessary at change environment. The system should flexible to attend more frequency of inspection and manage frequency of inspection without disturb current processes attending at places.

Reporting the stacking process

The stacking process is manage by assign personnel for managing and stacking materials at places as define by management for stacking materials. The stack each unit, materials should be indicate and proper organize where labels, sign boards, concern documents should manage and implement.

Like if the material having defect that it must be tagged “Defective” and report to higher authority that is responsible person for further actions on the defective materials on identify and tag. Hence the material stacking processes, organize documentation are important part of stacking process. Its inspection is done on documents by prepare reporting and checklist that helps to verify each requirements.

Stacking Inspection Checklist

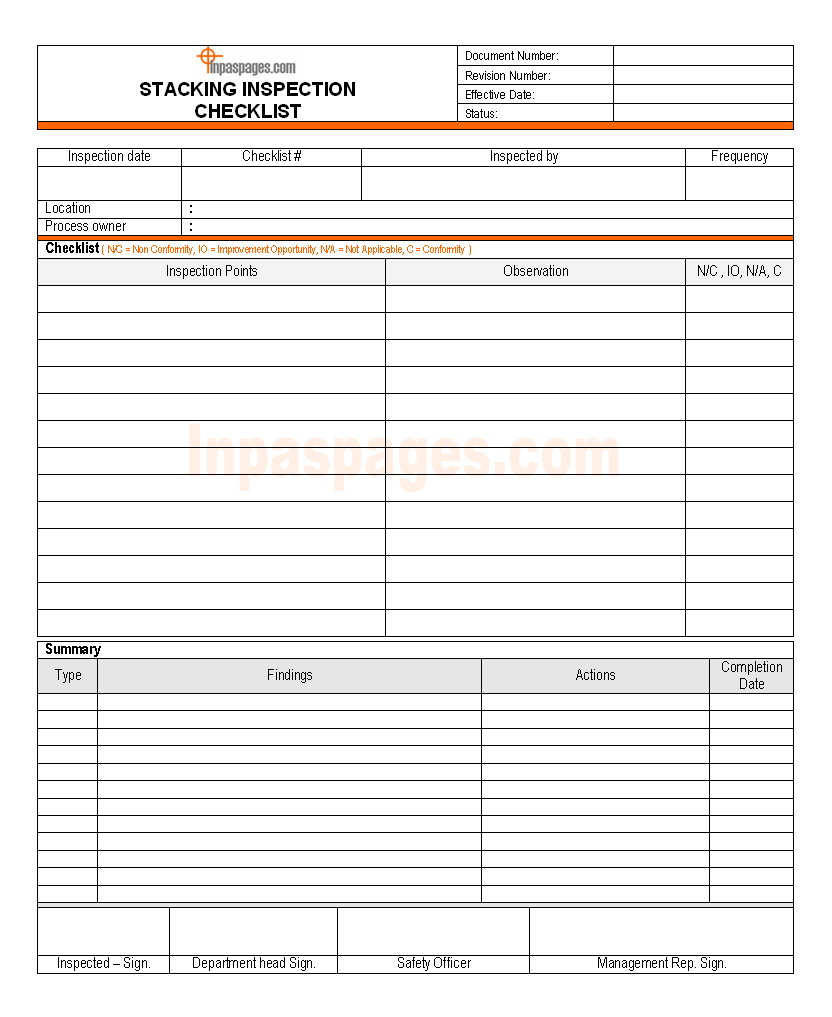

In the checklist format having all the necessary points that helps to inspection team to identify non-conformity and ensure conformity of product.

See picture below given as example format of stacking inspection checklist for education purpose only:

About Stacking inspection checklist

Stacking inspection checklist is format that use recording information, or verification of each processes, locations and condition of stack materials and appropriate locations. The inspection process is manage as per checklist pre-mention details where inspection team is verify the points. The observations are fill in the checklist to comply documentation requirements.

The detail information are manage in reporting of stacking inspection report which is submit to department head and management representative for further actions and implementation of various processes conduct in the places where materials stack.

Stacking implementation checklist points

See some basic points that help to implement checklist for stacking inspection:

- The materials should be stack as per height permit, verify the stacking lots as per standards limits.

- Whether staking areas should be neat, clean and tidy, there should not be superfluous materials is available, verify the all walkways & gangways proper line and define.

- Is there materials no stacks in danger of collapsing

- Whether how much ladders and mobile stairs are provided? there provided ladders are sufficient to manage tasks that easier for accessing top levels?

- are there maximum permissible loads display?

- Is there monitoring and supervision of stacking process done by a competent person?

- Whether stacking areas is defined? And the stack materials are segregated as category defined?

- Is the base used for stacking is sufficient for manage load or able to sustain weight exerted by stack? And base of stack is in good condition? Hence supporting structures are sufficient and able to manage load?

- Is there safety equipment, personal protective equipment etc., are used during handling processes? Persons are follows safety requirements and personal protective equipment at appropriate process?

Checklist description

The points above mention as used to managing checklist’s require processes. To verify the condition of stacking and inspection of activities conduct at stack place. The documentation, reporting and checklist is fill by inspection team as observation during audit / inspection processes. The submitting records to department head and management representative for further actions. The documentation used for improvement and compliance of non-conformity, improvement of opportunity identify during inspection process.

—————————————————————————-

Download format in word document | Excel Sheet | PDF format

Stacking inspection checklist

—————————————————————————-