In-process inspection is a quality inspection process, usually a method used to take samples randomly of the product during the production process.

Introduction to in-process inspection

The purpose of this instruction is to establish the process for the In-process inspection and testing activities to verify that the specific requirements for the product are met. The process is use to ensure the quality standards, product standards, product characteristics and customer expectations are meeting to the product. As well the inspection process also consider the end application requirements, and suitability.

Normally, the process is conduct to organize the product inspection, as per product standards as well as technical requirements. Generally this process conducts when process is on-going in production lines. It is real time inspection process. The qualified engineers are organize the process to using a various methods of inspection. The methods can be:

- Visual inspection

- Document inspection & verification

- Sampling inspection – Random sampling plan

Actually, the process conduct to review the job cards and sequence of process of product. It may be either process wise inspection or operation wise inspection. Generally, some of the important details such as job orders, technical details of product, customer’s end application, acceptable criteria etc. are consider during inspection process.

How to manage in-process inspection in workplace?

The quality team is responsible for managing the inspection process. They should follow procedures, guidelines and instructions for the proceeding the inspection. They will verify the product quality at each stage of the production lines, to ensure the product met the standards. There are some methods that may use for verify the process:

- Deploy monitoring tool – Verify the recording of the machine.

- Verification of the process sequences.

- Sampling plan, components testing and compositions of materials.

- Documentation & process cards verification

Normally, the sampling process may conduct by hourly basic, but it is depends on products and process sequence. More important is handling the inspection process with semantically. At the end of inspection process, all the inspection results may document with standard formats. Once the complete all the inspection process, quality engineer will be prepare the in-process inspection report.

In-process inspection report

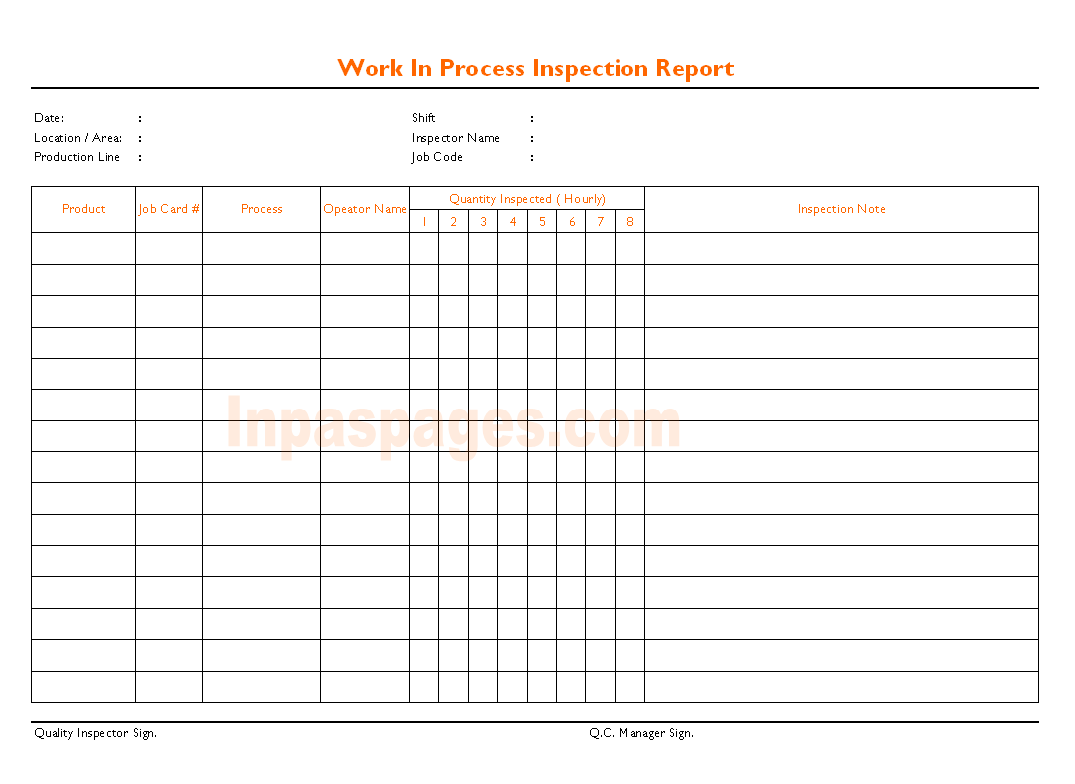

The quality engineer can use the standard report format as quality control’s standards documentations. Work in-process inspection report format is used to recording inspection process conducted in in-process at production lines. The inspection process can be schedule or as product requirements. But the inspection is manage for each hour by conducting sample by random process. Even the visual inspection of each product running at production lines can also perform if require. See picture below given as example format for education purpose:

About the inspection report

The inspection team is also manage the document inspection for verify the product running in production lines are maintain machine parameters, standards requirements, customer acceptable criteria, tolerances of dimensions etc. These are important part of the product quality and those factors are impacting on product quality and customer satisfaction.

The work in-process inspection process is important tasks for quality. That should be manage for each shift and locations. The team is manage internally which conditions and shift is verify for inspection. Team are deploy accordingly. The documentation for quality inspection is another part of quality inspection where all the documentation concern production lines are verify. The reports are manage by quality inspectors to reporting to quality manager for further actions. Hence the quality manager is verify the records and reviews records provide to management for determine actions in production lines improvement.

————————————————————————-

Download format in word document | Excel Sheet | PDF format

Work in-process inspection report

————————————————————————-