Traceability in manufacturing system

Traceability is method to ensure the materials are processing in the manufacturing processes is clearly identified, classified by system.

In manufacturing processes, raw material entered for the processing to producing finish product there is much possibility of material which is entered are shape, dimensions and properties are change that difficult to identify and trace the material in process. Raw materials through manufacturing area clearly identify and tracing that finished product should link from raw material by some unique system.

This process can apply in the manufacturing process where multiple stages and multiple locations in the company, manufacturing system if very completed, multiple site and stages that importance of the traceability is increase.

Traceability in manufacturing system depends on the identification of the product, once product, size, lot, batch etc.., is identify that product traceability is became simple and reliable for the manufacturing system.

Identification of the product or material for the tagging responsibility of planning peoples, they are schedule the production and assign unique number to all the products for manufacturing. There are also important that manufacturing peoples should take care of the material traceability go along with the material on each stage of the manufacturing process. Quality / packing peoples are also consider traceability tag as reference of the lot /batch for the quality inspection and packing the material to easier for the tracking the material lot which having any defects are found that corrective actions and preventive actions are easy for the management. Receiver should be take care on the internal transfer the material, each incoming raw material, semi finish material having with traceability tag and same should be out with it.

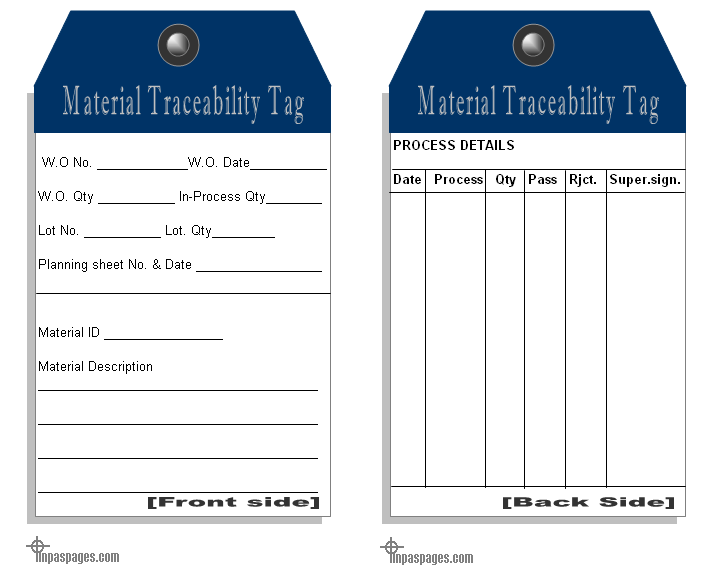

Material Traceability tag for product traceability through out manufacturing processes, the Material Traceability tag’s unique number helps to identify product in the manufacturing or rework process, all rework process of product are marked with manufacturing unique number which includes the job order / work order number for the base & future traceability. For the identification and traceability see picture below of material Traceability tag:

How to traceability in manufacturing system?

- Assign unique number for the traceability to al the batch number / lot number during the material planning / scheduling processes.

- On each material traceability tag having a each job number, work order or job card number what ever used in manufacturing should be mention in it.

- For the tagging, each raw material should be uniform numbers / lot /batch to easier for change the lot or batch number that tagging number will be automatically indicate the comfit that possible to tracking.

- All the material traceability tags are covered raw material to finish product until material are not packed.

Auditing of traceability in manufacturing system

- Traceability number is unique? Is there any duplicate number is provided?, is there sequences of the numbers are maintained uniformity.

- Product should be identified and categorized from raw material to finish product, on each production operations stages are maintain the tag for traceability. In the manufacturing processes are clearly mentioned with the material quantity and location process should be as per schedules.

- Manufacturing product batch or lot traceability should also covered all the tests are done on the manufacturing products and same should mentioned up to date on material traceability tag, there are also important that each lot / batch should clearly mentioned by quality department about how many quantity is taken for the testing and passed for next process.

- Traceability is not just a tag that indicating material identification, its should also helps to verify the material received by packing department are inspected, so auditor should inspect the packing material is inspected as per indicated in work order numbers.

Records of the traceability in manufacturing system are very important that all process stages, required information for the traceability and how to conduct the audits of the identification and traceability in the manufacturing system are documented.

Related Topic