Crane inspection checklist is use for verify the functions, mechanism and condition of the crane. It may helps to identify malfunctions of the crane, condition of spares & parts, maintenance status and overall components status.

Overview to Crane inspection checklist

Manufacturing company always required heavy machinery and equipment. Which is working to producing the material as end of finish product can possible. During the manufacturing process some equipment are supporting to production activities. In case of the failure of that equipment can stop the production activities, among the production supported equipment.

Overhead crane is most important equipment which is round o’clock working for the production activities. Mostly in engineering & engineering concern companies are working with heavy product or heavy material which needs to movement as routine works. Hence crane is important part of the production activities.

What may includes in crane inspection checklist?

In the crane / hoist inspection or audit process, competent personal responsible to conduct inspection / audit process at the prescribed intervals as designated. Crane inspection process should be inspected items at defined intervals. But it’s also necessary to plan inspection, for all the parts are inspect on once in annual.

In the goods moving / transportation heavy materials in plant level should be maintained / inspection required are:

- Functions – Up & down control, Load hooks, travel, Safety snap at in place, stop and run function, panel board, contact kit, slip ring and brushes, motor, switches.

- Physical – Rope & chain condition, hook load, main barrels & shelves, bumpers, end stop, wheels. Electrical interlocks, controls, emergency brake, connections,

- Safety – Cleaning & sweep, clearances, fire extinguishers, inspect track.

- Ringing – Slings, shakes, personal protective equipment and supporting equipment.

Check before use crane:

- Deterioration / leakage in pneumatic and hydraulic parts.

- Hooks with deformation / cracks – visual inspection

- Crane’ chains and connection for wear, twist / distortion

- Function operating mechanisms for excessive wear

- Operating mechanisms for instability

Overhead crane is working frequently for the production works that required maintenance, cleaning and lubrication process, timely inspection and replace or repair parts to increase productivity of the crane & minimize failures of the crane to run the production activities.

What can be frequency of crane inspection checklist?

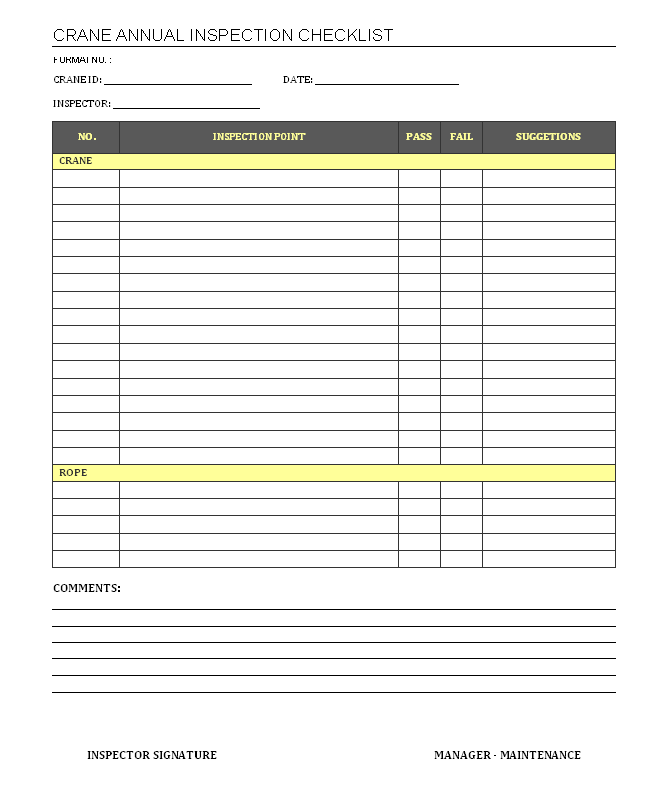

In the monthly or weekly inspection are mostly done in every company of the crane. But annual some extra inspection which is special for some part to ensure the crane parts are working properly & find out requirements of replacement of parts. For the crane annual inspection, mostly inspectors are use checklist which is pre-defined format as below:

- Crane Identification number

- Date of crane annual inspection Checked

- Inspector Name

- Inspection points, Pass, Fail as results

- Suggestion of inspector for the checked parts

EXAMPLES, SAMPLES & FORMATS: Download

Related Topics: