incoming material quality control procedure may help to sustain the standard practices for material handling, storage, inspection, and issue of incoming materials receive.

Overview to Incoming material quality control procedure

Incoming material quality control procedure establishment require for the recording information of all incoming materials from various sources. These materials are manage with documentation to ensure that the all incoming materials are receive as order given to vendor. Its quality are maintains by supplier to listing all the material arrival at the place.

Incoming material quality control process is manage by storage department. When all incoming materials records are inward, and tracking for the managing inventory in the organization. The daily materials arrival records handle to improve the system of inventory to tracking the materials receive from various suppliers. Here the steps of the process:

- The records are help to managing inventory where materials volume is high. The storage department is recording information of each incoming material receiving at the security points.

- Information and details are receive from against purchase order place to suppliers. The security points are provides information on the material receive from any suppliers.

- Than after the store department is collecting materials and related documents for further actions. The details information are mention in the daily arrival documents for materials are manage in the records.

- This documents are use for organize the materials, tracking the materials and verification of the purchase order place to suppliers.

- The pending order listing for procurement are also verify through this document, hence this document is important part of the storage department for the follow up for pending orders place to suppliers as internal department user requirements.

Daily Arrivals – Incoming materials documentation

Daily arrival documentation are establish by store department. The store department head is responsible for managing records of each incoming materials. All records are use to tracking and managing materials, the store department is receiving materials requirements from various department. The store department head is verify the requirements and generating purchase order to procuring materials from supplier as end user request.

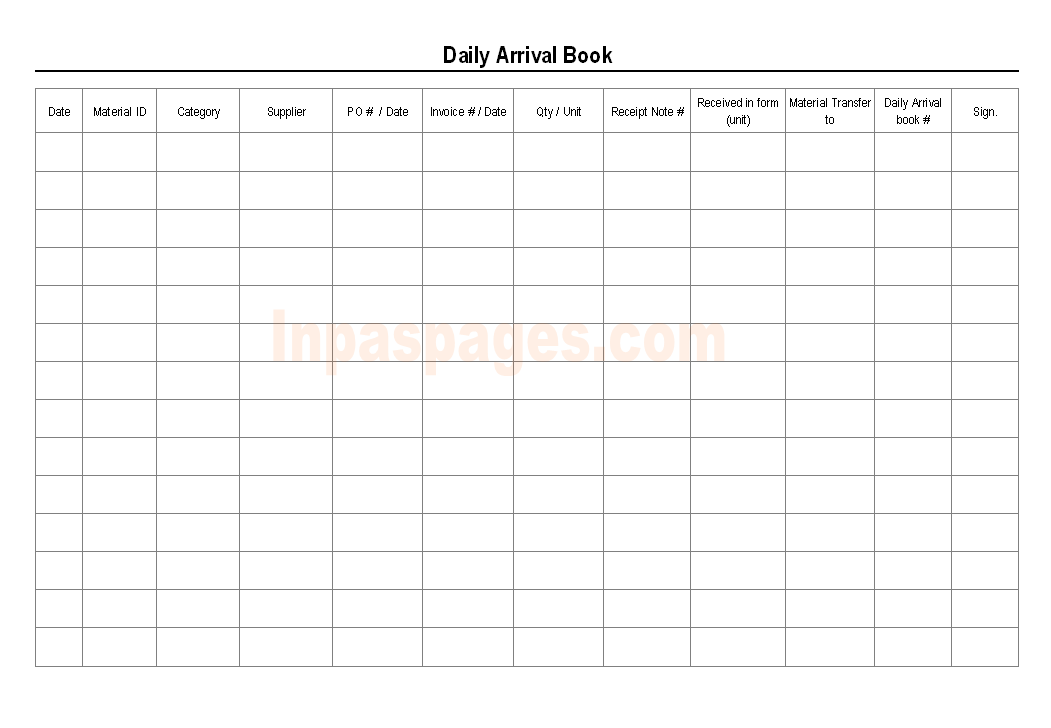

The request all the materials are comply, and verify when received, hence the records for the each materials are manage in daily materials arrival book, see picture below given as example format for education purpose:

Daily arrival book format

The daily arrival book format is use recording information on receive materials from supplier. Hence the records are manage for use to tracking the materials, organize materials and verify the pending order place to suppliers. The material records of each material arrive is manage in this format.

In the daily arrival book records describe details of material identification number, receive and order material details, supplier details, purchase order details, invoice. Its generate date, receive quantity against place order, receipt note, the important part of this format is receive in form. That is in unit that receive from supplier like we place order for numbers hence receive in boxes. Where pieces are involve in boxes, material transfer that receive are also mention in this format. To easier for tracking each records, and daily arrival book number is for tracking records are manage in this format.

————————————————————————–

Download format in word document | Excel Sheet | PDF format

Daily arrival book

————————————————————————–