Design plan improvement for product or services

Design plan improvement process for monitoring and controlling the design, planning and improvement of product or services

The process purpose is the describes the procedure for effective monitoring and controlling over the design segment, design planning of product and services, the process for the product and services depends & drawn the system to manage accurately is required to maintain quality of product or services, on planning and scheduling of the process to possible improvement by the defined criteria for monitoring and controlling over the design and development of product or services. Overall the purpose of the procedure is to providing for a system, instructions and standard procedures, and to assign responsibilities for the product or service design and design verification planning and controlling, validation activities and its improvement.

Design plan improvement process covered manufacturing, in-process activities and all engineering activities related to design, planning, sampling, production and sale raising in manufacturing activities of unit, the planning of design and its improvement is defined to practical improvement in-process activities by sampling planning and projection in the manufacturing and supporting activities. These procedures also applied to the design and development of new product, applicable handing and packing requirements and its improvement, and also apply to existing product modification and upgrades as per customer requirements and technical specifications.

Design Codification

In the Design planning very important part of the design and its improvement of the product or service is codification of each design separately to identification and traceability. The system of design codification method helps to effectively implement the design goals and part of the system to maintain stabilities of product’s design. The management and concern engineers should responsible for ensuring that the design codification and implementation of each design code separately. Here as below given example table for reference:

Design Codification Table

| Sr. No | Material Code | Material Serial | Design Code | Type of Design | Unique serial |

|---|---|---|---|---|---|

| 00 | MC001 | CST001 | TC001 | Bend | CSTC001B1 |

| 01 | |||||

| 02 |

As above you can see table for codification of design that helps to identification, traceability and managing each design in sequence for the documentation, planning, manufacturing processing to finalization of the product tracking, the codification system is easy and reliable to maintaining privacy. See above table codification, example given for reference as below:

- Material code given as MC001 that mean – material code 001 – describe material code.

- Material Serial – CST001 – here we taken CST ( Carbon steel tubes)

- Design Code – TC001 – here we taken TC(tube code)

- Type of Design is simple you can understand “bend” is type of tube being manufactured.

- Unique Serial – CSTC001B1 – CSTC ( Carbon Steel tubes Code) B1 ( Bend and design no.1)

As above simple and short code with unique codification system can possible to manage, even better to here describe you can maintain in your system, for the documentation and controlling the documentation system.

Design Planning & Improvement

All the designs and specification are to be inspected for entirety and for compliance with the standard requirement, designs are to be additionally inspected for standard tolerances, dimensional accuracy & check characteristics of product. On satisfaction of inspection of design plan and improvement project, verifications and validation processes are conducted, sampling and production of standard product shall carried out in as per controlled designed planning process, technical and concern documents and its revisions are maintained at the concern department. See below steps for the design planning and improvement.

- Design engineering team is responsible for managing product design, engineers are confirm the design with customer or customer is provide design for the product or services, design approval system is depends on the company management system, authority for the final approvals of design plan, inputs, design outputs, documents and design changes for final release of the design, finally customer is authorized to approve design after conformation of approval of design management.

- Design Planning and improvement are established for new product or services, process improvement or in the delivery of engineering services to customer, requirements of new products and process is accomplice based on customer requirements.

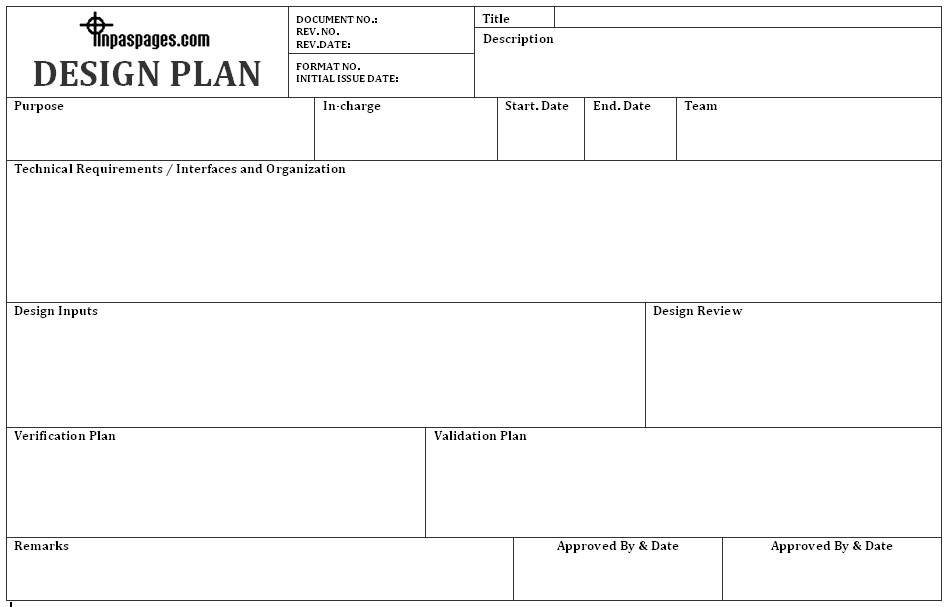

- All the concern peoples of the design and improvement team is consulting design activities, prior to commencement of any design planning activities, design engineers are preparing design plan format to comply requirement of the product and services, see below picture for the design plan format:

For the planning for the design and development required general inputs are – input of the previous design are main structural inputs, functional and performance requirements, regulatory and legal requirements as per government rules, estimate costing, environmental issues and solutions, safety requirements, concern personnel comments and suggestions.

- Design implement input are managing from marketing needs, technology updates, contract reviews and customer request, design inputs are collection and maintained in separate document to ensure the design inputs is properly documented.

- Designing team is conducted the concept of product like product brief, models, prototypes, sketches etc., requirements are conducted to evaluate clearance of specifications and characteristics of the product. In case of the further specifications are required that team should contacts the sources to compliances of specifications requirements of products.

Design outputs are recorded and documented, samples, models, data collection, drawing etc that specify the product and its produce standards. Design outputs are recoded for the verify to manner with the design inputs, the inputs of design requirements are applicable are – product specifications, documented processes, manufacturing specifications, product quality plants, prototypes, drawing, diagrams, product acceptances criteria, packing specification installation specifications, maintenance specification. Design outputs are uttered in conditions that can be verified against design inputs requirements.

Design reviews are conducted as scheduled in the planning, and as the required, the planning identifies required participants for design review. Design review can conducted as a meeting, through email system, video calling or conference, the management is responsible for ensure required functions are included in design review and reviews is conducted properly. Review shall provide assurance that design outcomes met the requirements are ensured through analysis, calculations, statistical method applying.

- A design team is evaluating the design input and output of the process and determines equipment of the inputs and design solutions.

- Design team verifying design to ensure that the design met design input requirements, and to review the design output.

- Review is conducted on the third phase, on completion of the production sampling and trail process, design validation with the desire of ensuring that the product meets customer and production requirements.

The design team verifies design outputs against design input by systematically identification in the design plan. The purpose of design verification is to ensure that all the outcomes form the design should be meet the design input’s requirements, design verification carried out at different stages of the design. Verification process is conducted on some generally used method like studies of the database, calculating dimensions and figures of the design, analysis of the collected data as design input and output, test the sample on base design is preceded, check the all concern information for the verification.

- Verification process is conducted for the verify design with the requirements of the standards, compare with previous designs and data to ensure the design upgraded and complying all the standard requirements.

- In verification process, all the collected data from the design planning, design inputs and outputs are analysis for identification of the risk factors, in the design is found accurate that implementation is possible in further phase.

- When the verification process is done and review verification results are acceptable that the team will proceed to design validation, if the results are not acceptable than the team will be determine possible changes, modifications and analysis the information.

Design validation is performed according to the design plan, validation activities includes some major requirements and activities that can be production trials by sampling planning, production process compare with the designs, customer trail up etc.. The process purpose of design validation is to ensure the product is met the requirements of the customers and its end applications.

- Design validation process or method is validate the all the stages of the process, supporting materials used to producing the material as per design is prepared, that can be product packaging material, labeling material, supporting parts etc., as the same that product will be finalized in each stages, each stages with the material used in its should be validated.

- Design validation activities should be as per planning and scheduling in the design planning sheet, results of the outputs are approved by customers and analyzed with end application.

When design validation is completed that mean the design planning and improvement of the design plan sheet is covered all the requirement of the design to producing the product and the product is complied all the requirement of the product specifications, criteria and standard requirements.

—————————————————————

Download Format in Word Document | Excel Sheet | PDF Format

Download Deign plan format

—————————————————————