Tool Room Management

Tool room inventory management

A tool room management is structural system provides for planning, tool procurement, inventory and controls on the tools movement functions.

Tool room management is complete system which all tools are procured, storage, handling and issues for the company’s internal used. This system provides to complete tool management solution from the planning of the tooling system for procurements, inventory management that helps to manage the tooling priority for procurements, storage and space managing and function used at end applications in the company. Tool room is the most important storage unit that can effect on the production line in case any miss management occurred.

The purpose of the tool room management is effectively supply tools in the production line, effectively tools supply mean that quick, perfect & defect free tools for the production. Mostly in engineering and manufacturing unit having frequently and huge used which need to in house facilities to manage, repair and provide tool in convention to production line activities. Reason for the independent tool room required management system which is directly concern with production line and production is depends on the tools requirements as and when needs that proper management is most important to maintain indents in manufacturing requirements by understanding of requirements of tools at production lines, perfection ( size, grade, specifications, properties etc.) of tool and zero defect tool that save the time and money of the production line to increase the productivities or maintain.

Motive of the tool room management is provides the effective system where tools are in house made and repairing services provides to manufacturing process lines that help to eliminate emergency situation of the tool requirements that results of manufacturing activities are not consequence.

- To design and manufacturing in house quality tools and provides as per requirements of manufacturing, production lines.

- To increase the efficiency of manufacturing processes by providing support in design and production of tools by technical consultancy.

- To eliminate emergency situation for the requirements of tools for production line.

- To cost controlling by effective and perfect designs to suitable of production requirements.

- To analyze requirements, frequencies of replacements, priorities managing of the requirements of the production.

- Support to productivity improvement of production lines by providing tools timely.

- To provide in house repairing services of tooling for cost cutting, time saving & active production lines.

The tool management cycle is started from internal tool requirements, in manufacturing processes is having the various types of machinery, instruments and equipment having requirements of tools that each requirements are comes to tool room which is managing tools for internal tool requisition, manufacturing processes will be shutdown if the tools are not timely fits as replace at new tools, hence each requirements of the tools are given to tool room. Manufacturing, production peoples are sending the requisition slip to tool room for the requirements of the tools. Each requisition slip are checked for the dimension of the tools and as per requirements tools are issues immediate or prepared tools on base of the dimensions are given by manufacturing team, if the material for the preparation of tools are not available that tool room procurement team is send the inquiry for the material procurement.

In the tool room generally types of inputs are as below:

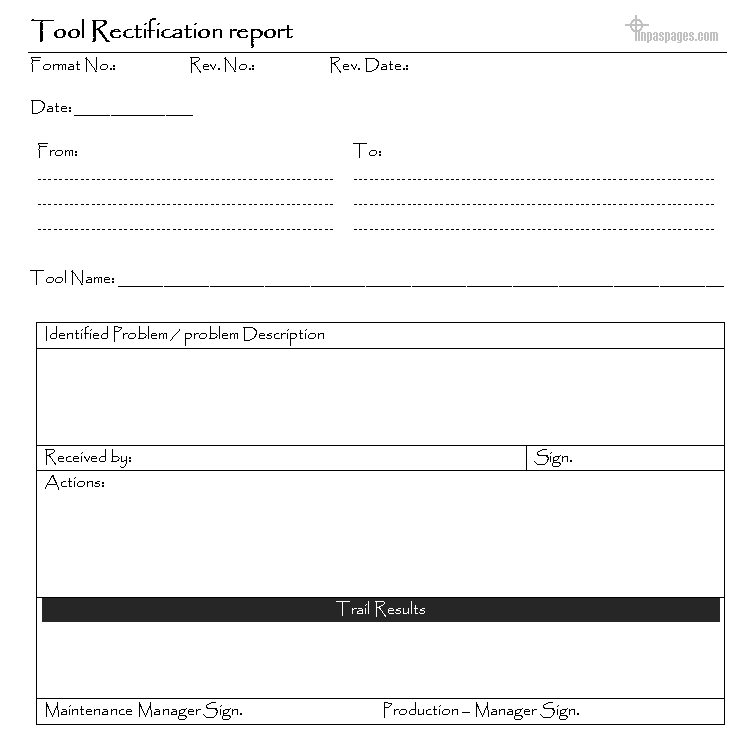

- Defective tools / replaced tools from manufacturing department – another inputs for the tool room is defective tools or tools from the manufacturing, production lines for the replacement or modification, all the defective tools or replacement / modification tools are conducted as inputs by the tools rectification form, manufacturing department needs to fill the format before the sending tools, the tools rectification form sends along with defective tool. In the tool rectification form having the all information which required for the replace, repair or modification defective / replacement of tools. Here as below given example format of tool rectification / modification report:

On base of the tool rectification form format, tool room is modifying the tools to fit the end application; the record of the each tool rectification form is manage by tool room department to recording and analysis purpose.

2. Incoming procured material for the tool raw materials – Tool room is considering requisition slip for the dimension, weight, sizes for the tool requirements which should fit at application, in case the tools are not available that tool room is placing purchase order to supplier of material. Supplier is sending the material for in house tools preparation.

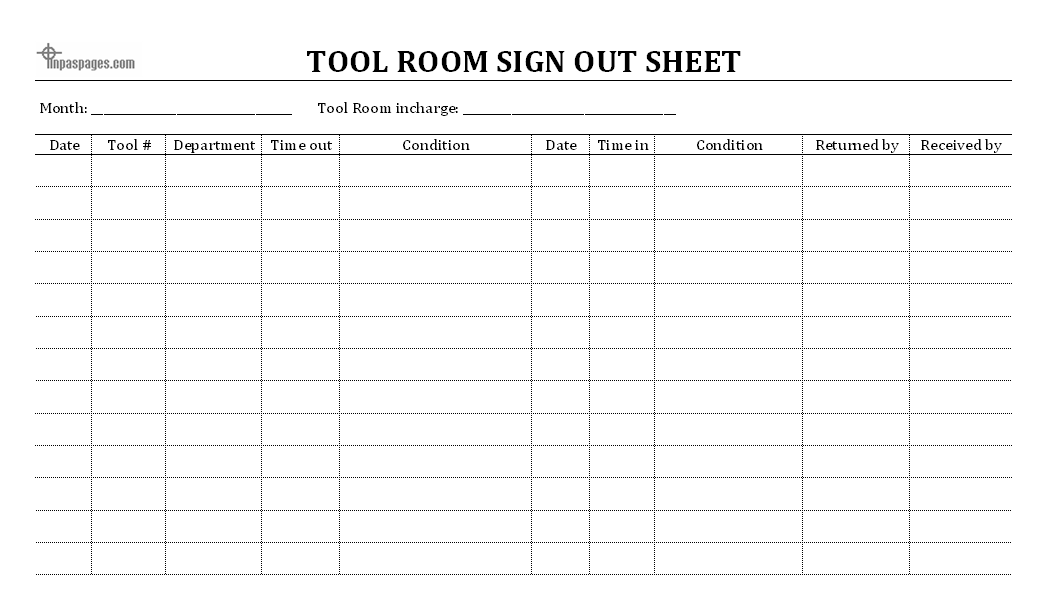

3. Returnable tools – When any department people having requirement of any tool for the some time that after the used of tool the tool room is collecting return back to inventory, mostly in manufacturing unit this kind of transitions are being where peoples are taken the tools for the fitting, checking or any other temporary used and fit at machine, equipment or any place that after complete the purpose person is returning the tool to tool room. Tool room conducting and managing all the returnable tools and made entry in the returnable tools registers which called as tool room sign out sheet. In engineering and manufacturing units having the frequently used of the tools for the internal purpose, hence this type of transitions made and tool room management should conducting the each transition for the maintaining inventory. See below picture of the tool room sign out sheet:

Tool room sign out sheet is simple log book which also called as tool room logbook is maintained by tool room in charge to manage all issued tools and returned tools from the individual department on completion of used. Tool room sign out sheet help to manage and conducting inventory transition of the tools which is returnable tools, those tools inventory is separately manage which are frequently used in production lines and managing as returnable tools.

Tool room inventory management

Tool room inventory management is important part which all the tools are checked and ensure accounting in order to confirm that all the tools are managed in order, in case any tool is lost or misplaced, damaged that tool record is separately maintain in the inventory system. Tool room inventory checking inspection frequency is defined by tool room manager to consider the requirements in manufacturing and daily or monthly transitions that possibilities of lost or misplace is higher that management of tool room is defined weekly inventory checking or monthly if the tools’ transition are not enough. There are also check in inventory each tool are stored in their appropriate location to easier for the tracking.

Inventory management is conducted on base of internal requirements, and tool room is managing inventory for the same. Inventory management should maintain re-order level system, in re-order level is level of the inventory stock of the tools that define on daily or monthly requirement of tooling, whenever tool stock is being lower than re-order level tool room management is add the quantity required to re-order level balance, this system is simple and useful for the reach the level of requisitions of manufacturing processes.

Inventory control is active part of inventory management, in the inventory control management is appoint the person who is responsible for inventory controls and authorized for the correction, error proof system and addressing procedural errors, actually inventory control is responsibility of every one whose are working in tool room, management is train the appointed person. Management is prepared the instruction, procedures and document control for the peoples are follows it’s and eliminate mistakes in inventory management. Authorized person is monitoring, inspect and adjust inventory variances, identify employee errors and correct error in inventory location. To actively monitoring, inspecting and proper documented procedures helps to inventory control.

Tool room – Tools Storage and Handling

In the tool room storage and handling is simple as consumable goods are maintain in storage areas, the purpose of the separately instructions of storage and handling process that helps to peoples are handle the tools in tool room. For storage and handling method used to preservation of tooling material. Here as below given table to help for managing storage and handling in tool room:

| Sr. No | Materials | Storage Method | Handling Method | Safety Requirements / System | Document Reference No. |

|---|---|---|---|---|---|

| 00 | Tool No. – I | Division Rack | Wheal Trolley | PPEs during operation | Doc.-005/TR |

| 01 | |||||

| 02 |

As above table, help to document all the process stages, individual tools to manage, handling and storage as per dimension, requirement of safety and also manage reference document that helps to tracking the tools.

Tool room management’s each stage should be proper documented, recorded and analysis should conducted for monitoring and control on activities, system steps for improvement in system.

———————————————————————————-

Download Format in Word Document | Excel Sheet | PDF Format

Download tool rectification report

Download tool room sign out sheet

———————————————————————————-