Basic Analysis of Kaizen – Steps of Basic Analysis

Kaizen Analysis

Kaizen analysis assistance to understand the problems, measure the status of problem, identification of root cause to implement innovative idea to resolve issues.

Kaizen is structural method procedures are used generally in manufacturing units. Where manufacturing concern problems are identified and its effective solutions are identify through Kaizen process. Which all the problems are managed by innovative ideas implement to permanent solutions for each problems are implemented. Kaizen analysis is part of the Kaizen process. All the department information are collected where information received from various department are used for analysis that is Kaizen analysis for each problem identified during the regular processes. Each problem is short out and manage separately for discuss in the general meeting, all the concern peoples are provides their idea and suitable idea is used for implement and eliminate problem at appropriate locations.

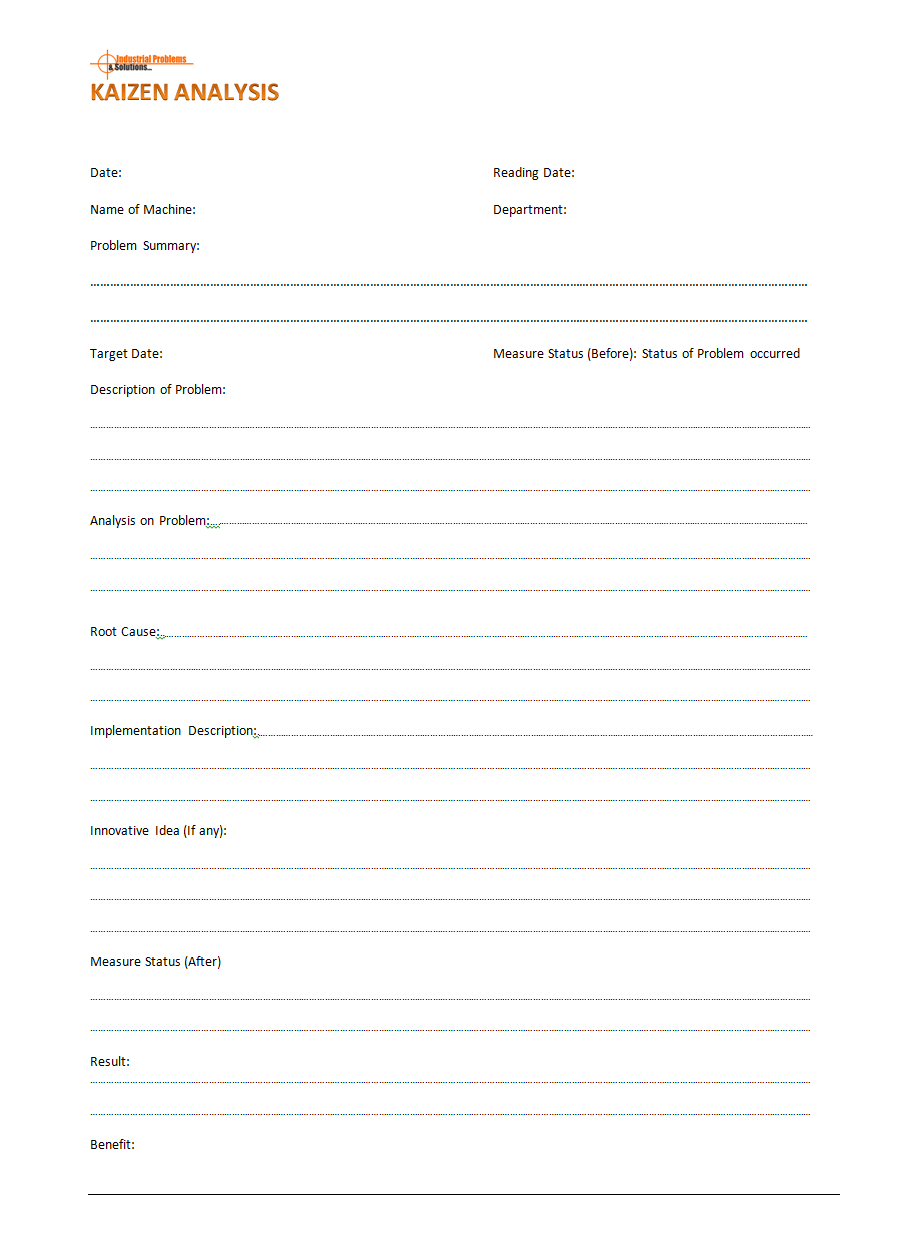

The management team is conducting the kaizen processes, implementation of all the feedbacks received from various department heads, sharing the information and idea during the general discussion. The information are used for the managing records of each problems and its solution in kaizen sheet, the analysis process is managed for each machine wise or locations recorded by appropriate locations and its supervisor. The analysis sheet is looking as below:

- Date: Date of Analysis Report Prepared

- Reading Date: Data Reading data

- Name of Machine:

- Department:

- Problem Summary:

- Target Date

- Measure Status (Before): Status of Problem occurred

- Description of Problem:

- Analysis on Problem:

- Root Cause:

- Implementation Description:

- Innovative Idea (If any):

- Measure Status (After)

- Result:

- Benefit:

See Example format: Kaizen Analysis

The organization use the Kaizen process for effective implementation of specified methods. It will be covered all the processes for implement. In case any problem identify during production activities, each process will manage for implementation and enhancement of reliability. Which will definitely improve product quality.

You Might Also Like:

Kaizen: